Silicone Seam Roller

What is a Silicone Seam Roller?

A seam roller is an essential hand tool for a sheet waterproofing membrane laying tasks. Silicone seam rollers have designed to press and smooth out seams during the hot air welding of waterproofing membranes such as PVC, EPDM, TPO, and tarpaulins. Using soft like silicone seam rollers for waterproofing membrane laying helps to ensure welded joints are properly bonded without bubbles or gaps.

These are the 4 main advantages of using a silicone seam rollers according to the Aqviz experts.

- High temperature resistance: Silicone withstands heat up to 250°C (482°F) without deforming during sheet membrane laying process.

- Smooth finish: Silicone surface is non-stick and it prevents membrane sticking and tearing with the higher temperature.

- Consistent pressure: Silicone seam roller consists of two-way bearings allow stable rolling, improving welding speed and bond strength.

- Ergonomic grip: The solid wooden handle of the silicone seam roller is comfortable, reducing hand fatigue during long welding sessions.

What is a Silicone Seam Roller?

A seam roller is an essential hand tool for a sheet waterproofing membrane laying tasks. Silicone seam rollers have designed to press and smooth out seams during the hot air welding of waterproofing membranes such as PVC, EPDM, TPO, and tarpaulins. Using soft like silicone seam rollers for waterproofing membrane laying helps to ensure welded joints are properly bonded without bubbles or gaps.

These are the 4 main advantages of using a silicone seam rollers according to the Aqviz experts.

- High temperature resistance: Silicone withstands heat up to 250°C (482°F) without deforming during sheet membrane laying process.

- Smooth finish: Silicone surface is non-stick and it prevents membrane sticking and tearing with the higher temperature.

- Consistent pressure: Silicone seam roller consists of two-way bearings allow stable rolling, improving welding speed and bond strength.

- Ergonomic grip: The solid wooden handle of the silicone seam roller is comfortable, reducing hand fatigue during long welding sessions.

Product Specifications

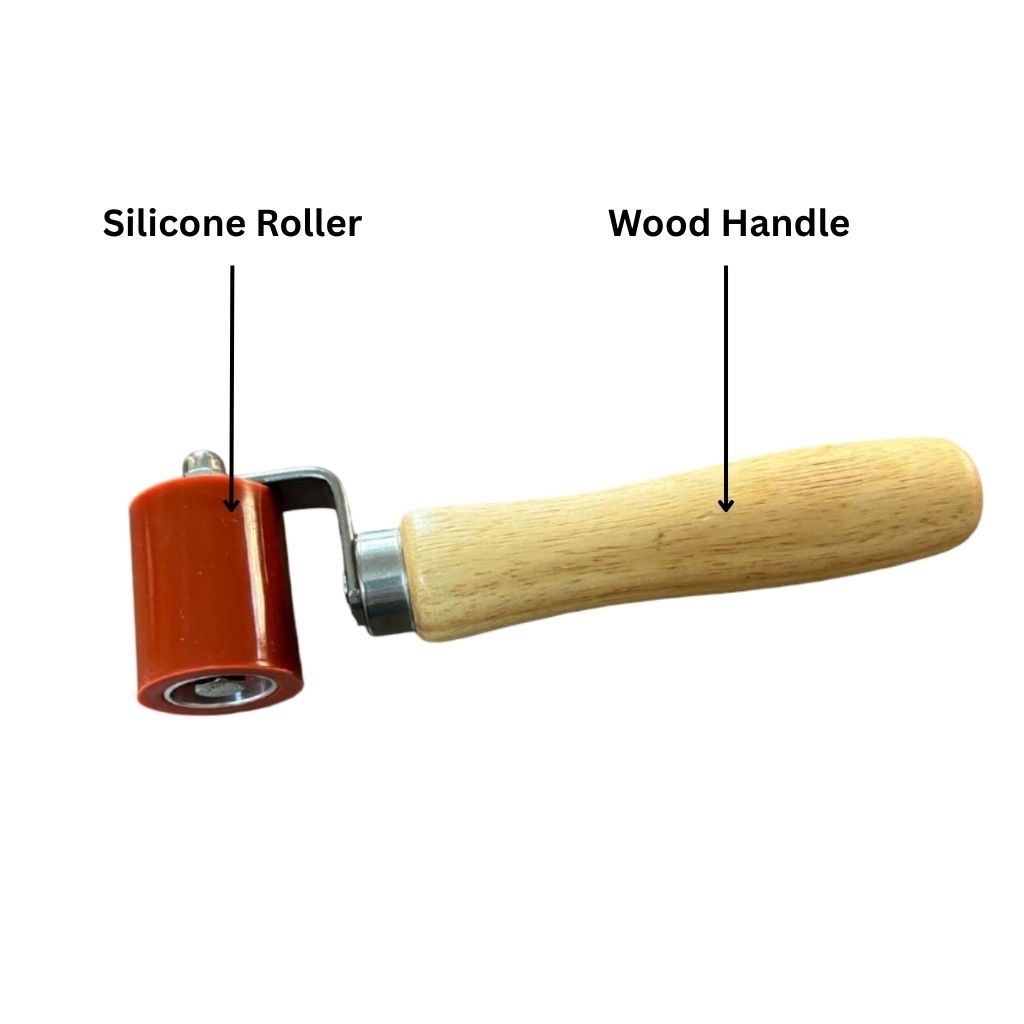

- Material: Silicone roller + Wooden handle

- Size: 180 x 50 mm

- Grade: DIY / Professional

- Warranty: None

- Color: Red roller, wooden handle

- Box contents: 1 × Hand pressure roller

How to Use a Silicone Seam Roller?

- Start hot air welding and overlap the membrane: First you should ensure your hot air welding gun is set to the correct temperature (PVC membranes: 260-350°C / 500-660°F ). Then overlap the membrane sheets according to manufacturer recommendations (usually 30-50 mm ).

- Welding with roller: Then you should direct hot air between the overlapping membranes, immediately press down with the seam roller. Don’t forget to apply firm, even pressure, rolling at a steady pace of 2-3 cm per second .

- Finish rolling: Finally allow the seam to cool for at least 2 minutes before performing a peel test. Then clean the silicone roller after use to avoid adhesive or residue buildup.

⚠️ Aqviz Experts highly recommend, you should never use metal rollers directly on PVC or TPO membranes. They can damage or puncture the sheet. Silicone rollers provide safe, heat-resistant contact.

Silicone Seam Roller Reviews

⭐️⭐️⭐️⭐️⭐️ – Aqviz Experts

Efficiency and smooth finish

Aqviz Recommendations

From our on-site experience, a seam roller is just as important as the welding gun . Without it, the heat alone won’t create a uniform bond. This silicone model stands out because:

- Pros of Silicone Seam Roller:

- Heat-resistant silicone ensures no sticking or burning, even during continuous welding.

- Two-way bearings give smooth motion, especially useful when working on long terrace joints.

- Ergonomic wooden handle reduces fatigue compared to plastic handles.

- Durable and wear-resistant, we’ve used a single roller on over 15,000 linear meters of seams without failure.

- Cons of Silicone Seam Roller :

- Only suitable for flat surfaces.

- Needs cleaning after every major job to prevent material buildup.

Where to Use Silicone Seam Rollers?

We highly recommend that you should use silicone seam roller for the followings.

- Balcony membranes

- Terrace and rooftop waterproofing

- Swimming pools and water tanks

- Tunnels and basements

- Tarpaulins and tents

- Flooring installations