TPO Roofing: Know Everything Before Installing

TPO roofing stands for Thermoplastic Polyolefin roofing, a single-ply membrane system widely used in flat and low-slope commercial roofing. TPO roofing mainly comes in six types. TPO roofing has superior water resistance capability, more flexibility, lasts up to 30 years, has excellent UV resistance, has moderate chemical resistance, and has excellent seam strength.

Although there are both pros and cons of TPO roofing, they are good for roofing due to UV reflective surface, strong seam integrity, compatible with insulation, mold and mildew resistance and cost-efficient installation. TPO roofing can be installed in both hot and extremely cold temperature environments due to its thermal stability. You should follow the expert guidelines mentioned in this guide during TPO roofing installation.

What Is TPO Roofing?

TPO roofing stands for Thermoplastic Polyolefin roofing, a single-ply membrane system widely used in flat and low-slope commercial roofing. It’s composed of a blend of polypropylene and ethylene-propylene rubber reinforced with polyester. TPO roofing typically comes in white, grey, and tan colors, with white being the most popular due to its high solar reflectivity (up to 0.79). TPO membranes are heat-weldable, UV-resistant, and offer superior flexibility. The standard thickness of the TPO roofing ranges from 45 mil (1.1 mm) to 80 mil (2 mm), meeting ASTM D6878 performance standards.

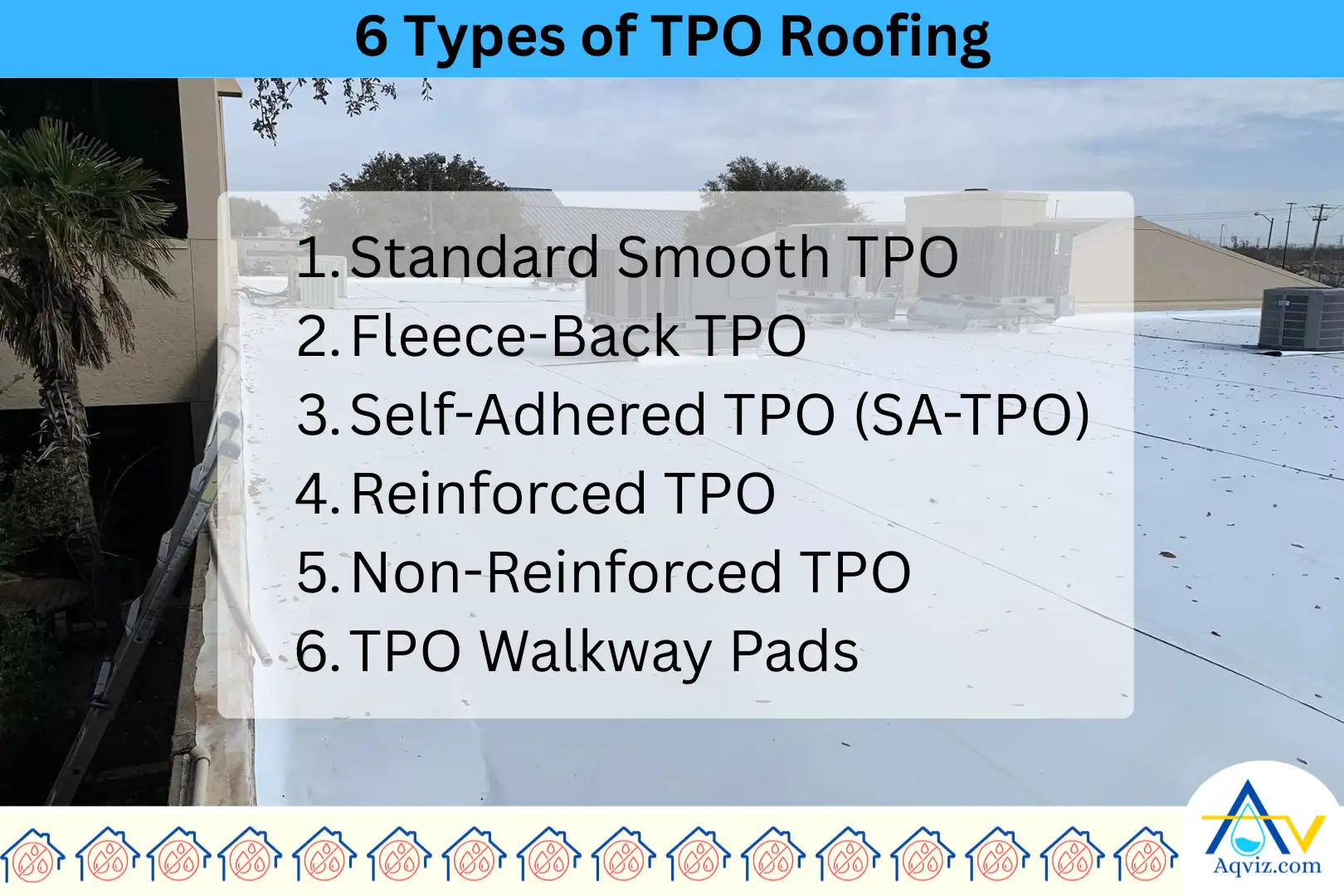

What Are the 6 Types of TPO Roofing?

These are the 6 types of TPO roofing and their best uses

- Standard Smooth TPO : The basic, smooth single-ply TPO membrane without any backing. These are best for new flat or low-slope commercial roofs.

- Fleece-Back TPO : TPO membrane bonded with a polyester fleece layer on the bottom. Fleece back TPO is best for re-roofing over old membranes or uneven surfaces.

- Self-Adhered TPO (SA-TPO) : TPO membrane with pre-applied adhesive and release liner. These TPO roofings are best for quick installations in clean, dry, warm conditions.

- Reinforced TPO : TPO membrane with embedded polyester or fiberglass scrim for added strength. Reinforced TPO roofing is best for high wind zones and roofs with heavy mechanical equipment.

- Non-Reinforced TPO : TPO membrane without any internal scrim or reinforcement. These roofing are best for flashing details, corners, and custom welding work.

- TPO Walkway Pads : TPO sheets with added thickness and surface texture for slip resistance. TPO walkway pads are best for access paths on roofs with frequent foot traffic.

Read More: What You Should Know About Roof Waterproofing?

What Are the Properties of TPO Roofing?

Key properties of TPO roofing

- TPO roofing has a superior water resistance capability

- TPO roofing is more flexible even in lower temperatures .

- TPO roofing lasts up to 30 years .

- TPO roofing has excellent UV resistance

- TPO roofing has a moderate chemical resistance , and TPO roofing offers solid fire and heat resistance

- TPO roofing has excellent seam strength

Water Resistance of TPO Roofing

TPO roofing provides superior water resistance due to its heat-welded seams, which create a continuous, watertight barrier unlike the adhesive seams in EPDM or modified bitumen systems. TPO shows lower water absorption rates (<1%) and better seam strength compared to PVC or built-up roofing (BUR). TPO seams can be three times stronger than tape-seamed EPDM, according to manufacturers like Firestone. It reduces leak risks over the membrane’s 20 to 30-year lifespan when properly maintained.

Flexibility of TPO Roofing

TPO remains flexible even in sub-zero climates. This makes it ideal for northern U.S. and Canadian regions where freeze-thaw cycles can split seams in stiffer materials. We’ve used TPO successfully in areas where PVC cracked over time due to rigid compounds. TPO’s thermoplastic nature allows it to accommodate building movement, minor settling, and thermal expansion, unlike modified bitumen or built-up systems.

Durability of TPO Roofing

TPO roofing is engineered for long-term durability with UV inhibitors, flame retardants, and anti-aging compounds embedded into the top layer. It resists punctures, tears, and impact damage, especially in the thicker 80 mil variants, which we often recommend for high-traffic roofs or facilities with regular maintenance access.

TPO shows better resistance to chemical exposure, microbial growth, and ozone degradation compared to EPDM and PVC roofings. Major manufacturers like Carlisle and Johns Manville back their TPO systems with warranties up to 30 years.

UV Resistance of TPO Roofing

TPO roofing is known for its excellent UV resistance, making it one of the top choices for sunny and high-altitude regions. At Aqviz, we’ve installed TPO on buildings in southern states like Arizona and Nevada, where it holds up against prolonged ultraviolet exposure without cracking or chalking.

TPO performs better due to its built-in UV stabilizers and reflective surface. While EPDM is black and absorbs heat compared to EPDM and modified bitumen roofings. White TPO membranes reflect up to 79% of solar radiation, reducing surface temperatures by 30-40°F (16-22°C).

Chemical Resistance of TPO Roofing

TPO roofing provides moderate to high resistance to many common rooftop chemicals, especially acids, oils, and industrial byproducts. But TPO roofing does not resist for petroleum products like gasoline, jet fuel, petrol, and kerosene. As well as TPO can be degraded by benzene, chlorine (gas), and chloroform when it is exposed.

Fire and Heat Resistance of TPO Roofing

TPO roofing offers solid fire and heat resistance, especially when installed over non-combustible insulation like polyiso or gypsum cover boards. TPO membranes meet Class A fire ratings per ASTM E108. TPO resists ignition and heat buildup and does not drip flaming material, making it a preferred system for buildings in wildfire-prone or high-heat zones.

Seam Strength of TPO Roofing

TPO roofing offers exceptionally high seam strength due to its heat-weldable thermoplastic seams, which fuse the membrane layers into a single monolithic surface. At Aqviz, we always highlight seam strength as one of TPO’s key advantages, especially for flat roofs exposed to wind uplift, foot traffic, or ponding water. In tests following ASTM D6878, TPO seams consistently outperform those of modified bitumen and BUR, which rely on layered overlap and mastic. This superior seam strength ensures long-term waterproofing and minimizes maintenance issues in commercial and residential applications.

Cost Comparison of TPO Roofing

At Aqviz, we always evaluate roofing systems not just on performance but also on cost-efficiency over time. Below is a cost comparison table showing average installation costs per square foot (USD) for various flat roofing systems, including material and labor in the U.S. market as of 2025:

| Roofing Type | Average Cost (USD/sq.ft) | Lifespan (Years) | Maintenance Level |

| TPO | $5.50 – $8.50 | 20 – 30 | Low |

| EPDM | $4.00 – $7.00 | 15 – 25 | Moderate |

| PVC | $6.50 – $9.00 | 20 – 30 | Low |

| Modified Bitumen | $3.50 – $6.50 | 10 – 20 | Moderate to High |

| Built-Up Roofing | $4.00 – $8.00 | 15 – 25 | High |

| Polyurethane (PU) | $6.00 – $10.00 | 15 – 20 | Moderate |

| Silicone Coatings | $3.00 – $5.00 | 10 – 15 | Low |

What Are the 5 Advantages of TPO Roofing?

There are 5 key advantages of TPO roofing compared to other flat roofing systems

- High energy efficiency : TPO roofing reflects up to 79% of solar heat , it helps to lower the HVAC costs in warm climates.

- Higher seam strength : TPO roofing seam strength is 3x stronger than EPDM . It helps to minimize the leak risk.

- Chemical and UV resistance : TPO roofing performs well in industrial areas with exhausts or UV exposure.

- Wide temperature range : TPO roofing stays flexible from -45°C to 110°C , perfect for cold and hot climates.

- Recyclable material : TPO roofing is Eco-friendly and fully recyclable, unlike asphalt-based or PVC roofs.

What Are the 5 Disadvantages of TPO Roofing?

There are 5 notable disadvantages of TPO roofing to consider before installation.

- Inconsistent quality : Some low-cost TPO roofing brands have varying formulation stability, especially in extreme heat zones.

- Shorter track record : TPO is newer than EPDM or BUR, so long-term real-world performance over 35+ years is still under review.

- Heat-welding expertise required : TPO roofing requires skilled installers to weld seams properly; poor workmanship can lead to seam failure.

- Surface scuffing : TPO roofing is more prone to cosmetic surface damage in high-foot-traffic areas unless reinforced.

- Limited color options : TPO roofing is mostly available in white, gray, or tan. It lacks color flexibility compared to PVC roofing.

Why is TPO Roofing Good for the Roof?

TPO roofing is a high-performance solution that combines affordability, resilience, and energy savings, which is why we at Aqviz frequently recommend it for commercial and residential flat roofs. Here are 5 reasons why TPO is a smart choice for roofing.

- Reflective surface : TPO roofing membranes reflect UV rays and reduce rooftop temperatures by up to 40°F (4.4°C) , lowering cooling loads.

- Strong seam integrity : TPO Heat-welded seams create a watertight bond that is stronger than glued seams in EPDM.

- Compatibility with insulation : TPO roofing works well with ISO and EPS boards. It helps to improve thermal efficiency (R-values up to R-6.5/inch).

- Resistant to mold and algae : TPO roofing resists biological growth without additional treatments.

- Cost-effective installation : TPO roofing is a lightweight membrane. It reduces labor time and structural reinforcement costs, keeping the total budget low.

In Which Climate Is TPO Roofing Recommended?

TPO roofing is highly recommended for both hot and cold climates, making it a versatile option for most U.S. regions. We recommend TPO especially for areas that experience extreme heat, intense UV exposure, or heavy rainfalls due to its weathering resistance and energy efficiency.

In hot southern states like Arizona, Texas, and Florida, TPO’s solar reflectance up to 0.79 significantly reduces building cooling costs. In northern regions such as Minnesota or Canada, its higher flexibility prevents seam cracking during freeze-thaw cycles.

How to Install TPO Roofing?

We follow six essential steps to install TPO roofing properly and in line with ASTM D6878 standards.

- Prepare the substrate : Clean the deck, remove debris, and ensure a smooth, dry surface free of sharp objects or moisture before installing TPO roofing.

- Install insulation board : Lay ISO, EPS, or XPS insulation panels and secure them using mechanical fasteners or adhesive before installing TPO roofing.

- Lay out TPO membrane : Roll out the TPO roofing membrane and let it relax to reduce tension; align sheets for consistent overlap (typically 6 inches).

- Secure the membrane : Use mechanical fasteners along the seams or fully adhere the sheet with bonding adhesive.

- Heat-weld the seams : Use a hot air welder (at around 1000°F or 540°C) to fuse TPO roofing membrane overlaps, forming waterproof, monolithic seams.

- Seal penetrations and flashings : Install pre-formed or custom flashings around HVAC units, drains, and walls using heat-welded detailing.

Can TPO Install DIY on the Roof?

TPO roofing can be installed DIY, but we at Aqviz strongly advise professional installation unless the installer has advanced roofing knowledge and access to specialized tools. TPO requires precise seam welding and detailed flashing work, which are difficult to execute without training.

DIY installation may work for small sheds or garages using peel-and-stick or self-adhered TPO sheets. However, most TPO systems require hot-air welders, which operate at up to 540°C (1000°F), making them unsafe and impractical for DIYers. Professional installers follow ASTM D6878 standards, ensuring seam strength, slope considerations, insulation compatibility, and wind uplift resistance. Improper DIY jobs often void manufacturer warranties and lead to premature failures like seam separation or ponding leaks.

How to Protect TPO Roofing?

To maximize the lifespan and performance of a TPO roof, Aqviz recommends 6 key protection methods every building owner should follow.

- Schedule regular inspections : Inspect the TPO roofing membrane twice a year and after storms to detect tears, uplift, or seam issues early.

- Clean the surface : Remove dirt, debris, and biological growth on TPO roofing every 6 to 12 months using soft brushes and manufacturer-approved cleaners.

- Use walk pads : Install reinforced walkway pads in high-traffic TPO roofing areas to prevent scuffing, punctures, and membrane abrasion.

- Protect flashings : Flashing details around HVAC, skylights, and drains should be sealed and reinforced to resist water intrusion.

- Avoid chemical exposure : Keep oils, grease, and harsh solvents off the roofing membrane, as they may degrade its surface layer.

- Maintain drainage systems : Clear gutters and scuppers to prevent standing water and structural strain from ponding on the roof.

What are the 6 Ways TPO Roofing Get Damaged?.

At Aqviz, we’ve repaired countless TPO roofs that were prematurely damaged due to poor handling, improper installation, or neglect. Here are 6 common ways TPO roofing gets damaged

- Improper seam welding : Weak or cold welds during installation can lead to TPO roofing seam separation.

- Using sharp tools carelessly : Dropping knives, screws, or tools on the TPO roofing during maintenance can puncture the membrane, especially thinner 45 mil sheets.

- Walking without protection : Frequent foot traffic without walk pads causes TPO roofing scuffing and granule loss. This can weaken the top layer over time.

- Chemical exposure : TPO roofing can be damaged by the oils, solvents, or degreasers due to HVAC units on the roof. These petroleum compounds can break down the TPO membrane surface.

- Trapped moisture under insulation : Poor substrate prep or wet insulation leads to TPO roofing blistering, membrane bubbling, and microbial degradation beneath the sheet.

- UV overexposure near rooftop equipment : Reflective glare or concentrated UV from metal surfaces can cause localized heat degradation or “thermal burns” on the TPO roofing surface.

Why is TPO Roofing Leaking?

Here are the most common reasons TPO roofing develops leaks.

- Improper seam welding

- Poor flashing installation

- Punctures from foot traffic or tools

- Aging or weathered membrane

- Clogged drainage systems

- Shrinkage and membrane pull-back

- HVAC unit condensation leaks

- Fastener back-out or misplacement

- Installation over wet insulation

- Damage from chemical exposure

- UV degradation on unprotected areas

- Poor overlap at seams or edges

Is TPO Roofing a Shingle?

No, TPO roofing is not a shingle. It is a single-ply membrane roofing system, not an individual or layered roofing unit like shingles. TPO comes in large rolls, typically 10 to 12 feet wide and up to 100 feet long, and is installed as a continuous sheet over the roof deck, not in overlapping pieces like shingles.

What are the 11 Roofing Types?

These are the most used 11 Roofing Types

- Standing seam metal roof

- Corrugated metal roof

- Stone-coated steel roof

- Clay tile roof

- Concrete tile roof

- Slate tile roof

- TPO roof

- PVC roof

- EPDM rubber roof

- Synthetic slate roof

- Composite shingle roof

What are the 9 Types of Waterproofing Membranes?

These are the most used 9 types of waterproofing membranes that are used for building waterproofing.

- EPDM (Ethylene Propylene Diene Monomer)

- TPO (Thermoplastic Olefin)

- PVC (Polyvinyl Chloride)

- Bituminous Membrane

- Modified Bitumen (SBS/APP)

- Rubberized Asphalt

- Polyurethane Membrane

- Cold-Applied Liquid Membrane

- Thermoplastic Polyolefin (TPO) Coating

Difference Between TPO and EPDM Roofing

Difference Between TPO and EPDM Roofing

Here’s a clear comparison between TPO (Thermoplastic Polyolefin) Roofing and EPDM (Ethylene Propylene Diene Monomer) Roofing roofing membranes, based on our experience at Aqviz.

| Feature | TPO Roofing | EPDM Roofing |

| Material Type | Thermoplastic membrane | Synthetic rubber membrane |

| Color Options | White, gray, tan (reflective) | Mostly black, limited white options |

| Solar Reflectivity | High (up to 0.79) | Low (black absorbs heat) |

| Seam Installation | Heat-welded (monolithic seams) | Tape or adhesive (less strong) |

| Flexibility | Moderate, remains flexible to -45°C | Excellent, flexible in all climates |

| Chemical Resistance | Moderate (resists common chemicals) | Poor against oils and solvents |

| Durability | 20–30 years with proper maintenance | Excellent with a white surface |

| Cost (USD/sq.ft) | $5.50 – $8.50 | $4.00 – $7.00 |

| Weight | Lighter than EPDM | Heavier membrane |

| UV Resistance | Excellent with white surface | Moderate (black absorbs UV) |

| Installation Surface | Best on flat/low-slope roofs | Also used on low-slope roofs |