Concrete Swimming Pools: Everything You Should Know

A concrete swimming pool is a permanent in-ground structure made with reinforced concrete. Concrete swimming pools are made of M25 or higher-grade concrete, rebars, and water-impermeable layers. You should maintain a depth of 150-200 mm (6-8 inches) for residential pools and 200-300 mm (8-12 inches) for large commercial or Olympic pools. The benefits of concrete swimming pools, when considering other types, are higher durability, custom design, higher surface finishing, increased structural strength, and a higher property value over time.

When you build a swimming pool, you should follow the steps below. And you should waterproof the swimming pool to enhance its performance. You can use waterproof paints, grouts, and plasters when constructing a concrete swimming pool. You will cost around 50,000 to 100,000 United States dollars for all of these tasks for the midsize swimming pools. And also you have to spend $5,000 to $10,000 for swimming pool waterproofing.

Concrete pool inner and outer walls have been built with different types of layers, which help to increase waterproofing capability and aesthetic appeal. In some cases, minor cracks can occur on the pool surface. This can cause the pool to leak, and stain marks can occur on the pool surface. TO prevent these problems, Aqviz experts highly recommend that you waterproof the swimming pool properly as well as maintain the pool properly. This helps to minimize the problems like cracks, leaks, efflorescence, algae growth, stain marks, rough surface and higher maintain cost of the swimming pool.

Aqviz experts highly recommend that you install a cementitious waterproofing membrane on the swimming pools. More than that, you can install PU, Epoxy, PVC, or HDPE, Acrylic coating, and Rubberized coatings on the pool deck and walls. You can waterproof both new and older swimming pools using these waterproofing membranes. If there are any problems related to concrete swimming pools, don’t hesitate to reach us. We will help you to solve that, and we are available for it 24/7.

What is a Concrete Swimming Pool?

A concrete swimming pool is a permanent in-ground structure made with reinforced concrete: a mix of cement, sand, aggregate, and water combined with steel rebar for strength and coated with a water-impervious layer to prevent water from penetrating through the concrete shell. Concrete swimming pools are the most durable and customizable pool systems available because they can be shaped to any size, depth, or design as per the user.

More than that, concrete swimming pools help extend durability, improve structural integrity, prevent cracks and leaks, enhance surface finish, and are easy to maintain and repair over time. As well as swimming pool waterproofing helps to increase these performances over time.

Which Concrete Is Best for a Swimming Pool?

The best concrete for a swimming pool is M25 or higher-grade concrete . M25 is a mix design to achieve at least 25 MPa (3625 psi) compressive strength after 28 days. At Aqviz, we prefer using M30 or M35 for high-end pools, especially in regions with aggressive soil or fluctuating groundwater levels. This grade ensures the pool shell has enough strength to withstand water pressure, soil loads, and long-term exposure to chemicals.

When using higher-grade concrete in swimming pools, it always helps control structural cracks, prevents water ingress, improves bonding with steel, improves durability, and allows precise shaping for the design.

In any case, if you use a lower-grade concrete, it causes frequent cracking, water leakage, poor bonding with reinforcement, reduced lifespan, and difficult shaping during construction.

How Deep Should a Concrete Swimming Pool Be?

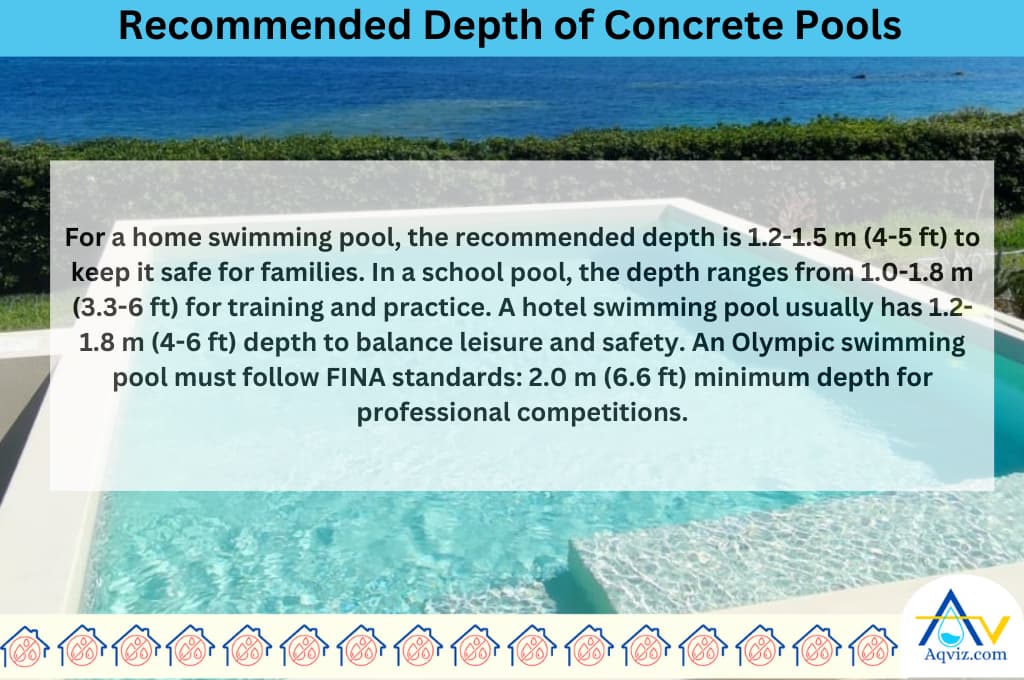

For a home swimming pool, the recommended depth is 1.2-1.5 m (4-5 ft) to keep it safe for families. In a school pool, the depth ranges from 1.0-1.8 m (3.3-6 ft) for training and practice. A hotel swimming pool usually has 1.2-1.8 m (4-6 ft) depth to balance leisure and safety. An Olympic swimming pool must follow FINA standards: 2.0 m (6.6 ft) minimum depth for professional competitions.

The depth of a concrete swimming pool depends on its purpose and usage: depth plays a major role in safety, comfort, and performance. At Aqviz, we always recommend designing pool depth according to user needs and following international standards for residential, commercial, and professional facilities. Proper depth planning prevents accidents and improves functionality for both recreational and competitive swimmers.

What Is the Concrete Thickness of a Swimming Pool?

The suitable concrete thickness for a swimming pool depends on size, soil condition, and water pressure. At Aqviz, we recommend 150-200 mm (6-8 inches) for residential pools and 200-300 mm (8-12 inches) for large commercial or Olympic pools. This thickness, combined with proper reinforcement and waterproofing, ensures the pool shell can handle hydrostatic loads and long-term use without distress.

If the concrete thickness decreases, it often leads to cracking, water leakage, and structural weakness because the shell cannot resist soil and water pressure.

On the other hand, if the thickness increases beyond the requirement, it raises construction costs, reduces workability, and may create uneven curing stress.

From our experience, striking the right balance in thickness gives the best durability and economy.

What Are the 5 Benefits of Concrete Swimming Pools?

There are 5 major benefits of concrete swimming pools. These are higher durability, custom design, higher surface finishing, higher structural strength, and increased property value over time.

- Higher durability: Concrete swimming pools withstand soil pressure, heavy use, and weather changes for over 30 years with minimum maintenance and repair.

- Custom design: Concrete swimming pools allow freeform shapes, varied depths, and unique features that fit any landscape.

- Higher surface finishing: Concrete swimming pools support tiles, quartz, plaster, epoxy, and pebble finishes for premium aesthetics.

- Higher structural strength: Concrete swimming pools resist cracking and shifting with reinforced shells.

- Increased property value: Concrete swimming pools improve property appeal and provide long-term investment benefits.

How to Build a Concrete Swimming Pool?

To build a concrete swimming pool, you should follow these 7 important steps. These are site preparation, excavation, reinforcement, concrete shell construction, waterproofing, finishing, and water testing.

- Prepare the site: First, you should mark the layout, check soil condition, and ensure proper drainage before beginning construction.

- Excavate the ground: Then dig the ground to the required depth and shape while maintaining slope stability.

- Install Reinforcement: Then you should place steel rebar mesh to strengthen the shell and resist soil and water pressure.

- Construct the concrete shell: Next, you should pour or spray high-grade concrete (M25-M35) at 150-300 mm thickness for structural strength.

- Waterproof the concrete shell: Then you should waterproof the pool by applying cementitious, polyurethane, or epoxy waterproofing to prevent leaks and efflorescence.

- Finishing: Next, add tiles, plaster, or pebble finishes for durability and aesthetic appeal.

- Test for the water: Finally, fill the pool, check for cracks, seepage, or leakage, and ensure the system is watertight before handover.

Read More About: How to Waterproof New Swimming Pool?

What Paints Can Be Used for Concrete Swimming Pools?

When you choose paints for swimming pools, they should have higher water resistance, chemical resistance, UV stability, strong adhesion, and a smooth finish. By considering these factors, Aqviz experts use the below 7 best paint brands in the US market.

- In The Swim pool paint

- Olympic Zeron Epoxy pool coating

- Rust-Oleum Pool & Fountain paint

- Ramuc pool paint

- Kelley Technical Olympic Optilon

- Dura Seal Epoxy pool paint

- National Pool Finishes

What Is the Average Cost of a Concrete Swimming Pool?

The average cost of a concrete swimming pool is 50,000 to 100,000 United States dollars. The average cost depends on size, depth, design, and finishes. This cost includes excavation, reinforced concrete shell, plumbing, filtration, and surface finishes such as tiles or plaster. Larger pools with custom features like waterfalls, spas, or lighting can exceed $120,000.

Waterproofing costs for the swimming pool typically add $5,000 to $10,000 to the project. This includes cementitious coatings, epoxy, or polyurethane membranes that prevent leaks and efflorescence. Proper waterproofing helps to reduce the long-term repair expenses, prevents cracks from water pressure, and extends the pool’s lifespan by decades.

What Are the Essential Layers in a Concrete Swimming Pool?

There are 5 essential layers in a concrete swimming pool. These are a structural concrete shell, a waterproofing layer, plaster or screed, tile adhesive with grout, and a final surface finish.

- Structural concrete shell: The structural concrete shell acts as the backbone of the swimming pool, resisting soil pressure and water loads.

- Waterproofing layer: The waterproofing layer protects the swimming pool against seepage, efflorescence, and cracks caused by water ingress.

- Plaster or screed: Plaster or screed levels the swimming pool surface and provides a smooth base for tiling or finishing.

- Tile adhesive with grout : Tile adhesive with grout ensures swimming pool tiles are firmly fixed while grout seals the joints to prevent leaks.

- Final surface finish: Final surface finish includes tiles, quartz, epoxy, or pebble that give the swimming pool durability and aesthetic appeal.

What Are the Stain Marks in a Concrete Swimming Pool?

Stain marks in a concrete swimming pool are discolorations that appear on the surface inside or outside the swimming pool, often leaving brown, white, or green patches that affect the appearance and durability of the structure. These stains usually indicate chemical imbalance, water seepage, or material deterioration in the swimming pool.

There are 5 main reasons for stain marks in a swimming pool:

- Mineral deposits: Calcium and salt deposits create white efflorescence on pool walls and outside surfaces.

- Metal contamination: Iron and copper in water cause brown, black, or green stains on the pool finish.

- Algae growth: Poor circulation and sanitation allow algae to embed into the porous surfaces of the pool.

- Water seepage: Continuous leaks leave damp patches and discoloration around the pool structure.

- Chemical imbalance: Incorrect pH and chlorine levels damage finishes and lead to staining.

To minimize the stain marks in the swimming pool, you should install a proper waterproofing membrane on the surface. It helps to prevent water seepage through the concrete layer and stops the stains marks on the surface.

How Do You Properly Maintain a Concrete Swimming Pool?

There are 7 important steps to properly maintain a concrete swimming pool. These are regular cleaning, water testing, chemical balancing, filtration check, brushing walls, inspecting waterproofing, and scheduled servicing.

- Clean the pool regularly: First, you should remove leaves, debris, and dirt from the swimming pool surface and floor to keep the water clear.

- Test the water quality: Then, you must test pH, chlorine, and alkalinity levels in the swimming pool at least twice a week to avoid imbalance.

- Maintain the chemical balance: Next, you should maintain proper chemical levels to prevent algae growth, scaling, and corrosion inside the swimming pool.

- Check the swimming pool filters: You must clean swimming pool filters regularly and ensure circulation systems are functioning efficiently to keep water fresh.

- Brush the pool walls: You should brush the pool walls and floor weekly to remove algae, stains, and calcium deposits.

- Inspect the waterproofing: Then, you must check for cracks, leaks, and efflorescence around the swimming pool shell.

- Scheduled servicing: Finally, you should arrange professional swimming pool inspection and servicing at least once a year for long-term durability.

Why Do Concrete Pools Crack?

Concrete pools are cracked due to these 5 major reasons such as soil movement, improper curing, temperature changes, structural overload, and poor waterproofing.

- Soil movement: Concrete swimming pools crack due to unstable soil or ground settlements. This causes uneven pressure on the swimming pool shell, leading to cracks.

- Improper curing: Concrete pools crack when concrete is not cured correctly. This results in shrinkage and weak structural strength.

- Temperature changes: Concrete pools crack because expansion and contraction from hot and cold weather create stress on the shell.

- Structural overload: Concrete pools crack if excess water pressure or insufficient reinforcement overloads the concrete shell.

- Poor waterproofing: Concrete pools crack when water penetrates the shell, weakens the concrete, and causes surface deterioration.

Read More About

Why Do Concrete Swimming Pools Leak?

Concrete swimming pools leak due to these 5 major reasons such as structural cracks, plumbing failures, poor waterproofing, tile grout damage, and joint weakness.

- Structural cracks: Swimming pools leak when cracks form in the concrete shell, allowing water to escape through the structure.

- Plumbing failures: Swimming pools leak if pipes, fittings, or returns embedded in concrete develop leaks or disconnections.

- Poor waterproofing: Swimming pools leak when waterproofing layers are improperly applied or deteriorate over time.

- Tile grout damage: Swimming pools leak if tile joints lose grout, creating small passages for water seepage.

- Joint weakness: Swimming pools leak due to weak expansion joints between the shell and coping or surrounding deck.

How Do You Prevent Leaks in a Concrete Swimming Pool?

To prevent concrete swimming pools leaking you should waterproof the swimming pool, use quality concrete, install sound plumbing, maintain tile grout, and inspect expansion joints.

- Waterproof the swimming pool: You should waterproof the swimming pool by installing cementitious membranes, polyurethane membranes, or epoxy coatings. It helps to prevent minor and major cracks and seepage through the concrete layer.

- Use quality concrete: You should use high-grade concrete such as M25 or above with proper curing. It prevents shrinkage cracks and improves the structural strength of the swimming pool shell.

- Install sound plumbing: You must install durable PVC or CPVC pipes with proper sealing and pressure testing. It prevents hidden leaks inside the swimming pool structure.

- Maintain tile grout: You should maintain and reapply waterproof grout in the joints of swimming pool tiles. It reduces water penetration through gaps into the shell.

- Inspect expansion joints: You must check and seal swimming pool expansion joints with flexible sealants. It stops water loss between the coping and the concrete shell.

What Are the Problems With Concrete Swimming Pools?

There are 7 common problems with concrete swimming pools. These are cracking, leaking, efflorescence, algae growth, staining, rough surfaces, and high maintenance costs.

- Cracking: Concrete swimming pools often develop structural or shrinkage cracks due to soil movement, curing issues, or heavy loads.

- Leaking: Concrete swimming pools can leak through shell cracks, faulty plumbing, or weak waterproofing layers.

- Efflorescence: White salt deposits appear on swimming pool surfaces when water seeps through concrete and evaporates.

- Algae growth: Porous surfaces in concrete swimming pools encourage algae buildup if chemical balance is poor.

- Staining: Concrete swimming pools develop stains from minerals, metals, and organic matter in the water.

- Rough surfaces: Over time, plaster or concrete finishes in swimming pools wear out, becoming abrasive and uncomfortable.

- High maintenance cost: Concrete swimming pools require frequent repairs, resurfacing, and chemical adjustments compared to other types.

What Waterproofing Method Is Good for Concrete Swimming Pools?

The best waterproofing method for concrete swimming pools is cementitious waterproofing because it bonds strongly with concrete, resists hydrostatic pressure, and provides a long-lasting protective barrier inside the pool shell. It also allows easy application on irregular surfaces and is highly compatible with tiles and finishes.

Other suitable waterproofing methods include:

- Polyurethane membranes: Flexible coatings that prevent cracks and seepage caused by ground movement.

- Epoxy coatings: Chemical-resistant finishes that protect swimming pools from chlorine and salts.

- PVC or HDPE liners: Prefabricated sheets that create a watertight barrier inside the swimming pool.

- Acrylic coatings: Cost-effective waterproofing options that add durability and resist UV rays.

- Rubberized coatings: Highly elastic solutions that cover microcracks and improve pool longevity.

Concrete vs. Fiberglass Swimming Pools: What Are the Differences?

There are 5 main differences between concrete swimming pools and fiberglass swimming pools. These are related to design flexibility, installation time, surface durability, maintenance needs, and overall cost.

- Design flexibility: Concrete swimming pools allow unlimited shapes, depths, and custom features, while fiberglass swimming pools come in pre-molded factory shapes with limited options.

- Installation time: Concrete swimming pools take 3-6 months to build, while fiberglass swimming pools can be installed in 2-4 weeks.

- Surface durability: Concrete swimming pools offer strong finishes like plaster, quartz, and tiles, while fiberglass swimming pools may develop surface gel coat issues over time.

- Maintenance needs: Concrete swimming pools require regular resurfacing, cleaning, and chemical balancing, while fiberglass swimming pools need less maintenance.

- Overall cost: Concrete swimming pools cost $50,000–$100,000, while fiberglass swimming pools range from $35,000-$70,000 with fewer long-term repair costs.

Can You Build a Swimming Pool out of Concrete Blocks?

Yes, you can build a swimming pool out of concrete blocks, but it is not as durable as a reinforced concrete pool. Concrete block pools require additional reinforcement, proper mortar joints, and full waterproofing membranes to prevent seepage. Without these, the joints between blocks may weaken and cause leaks. Concrete block pools are more affordable but often need more maintenance and repair over time compared to solid concrete pools.

What Are Precast Concrete Pools?

Precast concrete pools are factory-made pool shells manufactured using high-strength reinforced concrete. These shells are cast in controlled environments, cured properly, and then transported to the site for installation. Precast concrete pools reduce construction time, improve quality control, and ensure uniform waterproofing. They are durable, customizable, and often more cost-efficient than traditional cast-in-place concrete swimming pools.