Ultimate Guide for Bituminous Sheet Waterproofing

Bituminous sheet waterproofing is a pre-manufactured bitumen-based membrane reinforced with polyester or fiberglass which is used to protect structures from water infiltration. All of the bitumen sheets are highly water resistant. When it is applied on the substrate it will be highly waterproofing over time. Bitumen sheets are available as rolled and flat types.

The main bitumen two types are SBS modifies and and APP modified bituments. These sheet waterproofing membranes can be applied as torch membranes and cold applied membranes on the substrate. The standard thickness of the bituminous sheet waterproofing ranges between 3mm to 5mm but its thickness can be varied with the usage purposes. Bituminous sheet waterproofing is breathable, UV resistant, and chemically resistant due to these properties it can last about 20-30 years when it is properly maintained.

Bituminous sheet waterproofing can be adhered to the surface by using a torch membrane, hot adhesives, and cold adhesives. You should maintain at least 75mm to 100mm of overlap to join the bitumen sheet for better waterproofing over time. You can use bituminous waterproofing on roofing systems, basements, foundations, tunnels, bridges, decks, and more. Extremely bad environmental factors can affect negatively the bituminous sheet waterproofing if it is not treated properly and on time.

So Aqviz, we highly recommend you to prepare the surface properly, install the sheet waterproofing properly, and protect it from the harsh environmental conditions in order to long lasting the sheet waterproofing membrane on the substrate.

What is Bituminous Sheet Waterproofing?

Bituminous sheet waterproofing is a pre-manufactured bitumen-based membrane, reinforced with polyester or fiberglass which is used to protect structures from water infiltration. Bituminous sheet waterproofing consists of providing excellent tensile strength and elongation properties. These sheets are commonly used in below-grade waterproofing, roofing, and wet areas where superior water resistance is required. The bituminous composition offers strong adhesion, ensuring seamless protection against moisture, hydrostatic pressure, and environmental wear.

At Aqviz, we have extensive experience with bituminous waterproofing membranes in residential and commercial applications. From basements to terraces, we’ve seen how these sheets withstand extreme weather conditions and structural movements. In order to have a longer lifespan of the membrane we highly recommend you to prepare the substrate properly and ensure proper overlaps during installation.

If you are not able use bituminous sheet waterproofing, you can use these 10 Types of Waterproofing Membranes to seal your structure from water.

What Bitumen Sheets Are Waterproof?

Most bituminous sheets used in waterproofing are designed to be 100% impermeable to water and moisture. However, their effectiveness depends on the type of reinforcement, bitumen modification, and installation method. There are two main categories: APP (Atactic Polypropylene) modified bitumen sheets and SBS (Styrene-Butadiene-Styrene) modified bitumen sheets. APP membranes are ideal for high-temperature environments and are typically applied using the gas torch, while SBS membranes offer greater flexibility and adhesion, making them suitable for cold climates and complex substrates.

Through our hands-on work, we have observed that

- Reinforced polyester-based bituminous sheets provide better elongation and flexibility.

- Fiberglass-reinforced sheets excel in dimensional stability and fire resistance.

- Modern self-adhesive and self-protected mineral-coated bituminous membranes provide enhanced durability and UV resistance.

What Are the Modified Bitumen Sheets?

Modified bitumen sheets are advanced waterproofing membranes that have been enhanced with polymer additives to improve flexibility, durability, and adhesion. These sheets incorporate elastomeric or plastomeric compounds such as SBS (rubberized asphalt) and APP (plastic-modified asphalt), making them more adaptable to temperature changes and structural movements. Modified bitumen sheets are available in various thicknesses (typically 3mm to 5mm) and can be applied as a torch, self-adhered, or hot-mopped.

What Is the Difference Between Modified and SBS Bitumen Sheets?

Modified bitumen sheets is a general term that includes both APP and SBS-modified membranes, whereas SBS bitumen sheets specifically refer to membranes modified with Styrene-Butadiene-Styrene (SBS) rubber. SBS-modified sheets offer superior flexibility, elongation (up to 6 times their original length), and better adhesion to substrates. Hence SBS-modified sheets work well in regions with extreme cold. APP-modified sheets use polypropylene. It helps to enhance heat resistance and UV resistance. Hence APP can be used for high-temperature regions and direct sunlight exposure.

What Are the Two Types of Bitumen Sheets?

Bituminous waterproofing sheets are classified into rolled bitumen sheets and flat bitumen sheets, depending on their form and application method. Rolled bitumen sheets are the most commonly used type and it is supplied in 8 to 10-meter rolls. Rolled bitumen is easy to transport, store, and apply. These sheets are installed using a gas torch, self-adhesion, or cold-applied adhesives. Rolled bituminous are extremely suitable for roofs, basements, and underground waterproofing.

On the other hand, flat bitumen sheets are pre-cut or factory-formed into specific panel sizes, often used in waterproofing applications that require precision, such as foundation walls, bridge decks, and complex architectural features. Unlike rolled sheets, which are flexible and can conform to surfaces, flat sheets are more rigid and require mechanical fastening or full adhesion to ensure watertightness. In our experience at Aqviz, rolled sheets are preferred for continuous waterproofing systems, while flat sheets are used in high-load areas such as damproofing.

How Thick Is a Waterproof Bitumen Sheet?

The thickness of waterproof bituminous sheets varies based on their application, reinforcement, and performance requirements. Standard thicknesses range between 3mm and 5mm, with heavy-duty sheets reaching up to 6mm. A 3mm sheet is commonly used in damp-proofing or single-layer waterproofing applications, while a 4mm to 5mm sheet is preferred for multi-layer systems like high-exposure areas, and heavy-duty waterproofing.

Is Bituminous Sheet Breathable?

No, bituminous waterproofing sheets are not breathable. They form a continuous, impermeable barrier that prevents both liquid water and water vapor from passing through. This characteristic makes them ideal for basements, foundations, and roofs, where absolute waterproofing is necessary. However, in applications where moisture control is required, we integrate venting layers or drainage mats to allow trapped moisture to escape, preventing condensation buildup.

At Aqviz, we’ve encountered cases where improper installation of bituminous sheets led to moisture entrapment, causing blistering, delamination, and mold growth. To avoid such issues, we recommend preparing the substrate properly, ventilation design, and controlling the vapor inside the substrate.

Is Bituminous Sheet UV Resistant?

Yes, bituminous sheets can be UV-resistant, but their resistance depends on their surface treatment. Standard bitumen sheets degrade under prolonged UV exposure, but mineral-coated or reflective-coated sheets significantly improve UV resistance. APP-modified bituminous sheets have superior heat and UV stability, making them suitable for exposed roofs, terraces, and podium decks.

Is Bituminous Sheet Chemical Resistant?

Yes, bituminous sheets offer good chemical resistance, particularly against acids, alkalis, salts, and industrial pollutants. Their chemical stability makes them suitable for wastewater treatment plants, chemical storage areas, and structures exposed to aggressive environments. However, bituminous membranes can deteriorate when exposed to petroleum-based solvents, strong hydrocarbons, or extreme pH conditions, which can cause softening or loss of adhesion.

How Long Can Bituminous Sheet Waterproofing Last?

On average, a well-installed SBS or APP modified bituminous membrane can last 20 to 30 years. However, in harsh weather conditions, high UV exposure, or heavy traffic areas, the longevity may be reduced to 15 to 20 years without proper protection. The lifespan of bituminous sheet waterproofing depends on material quality, installation technique, exposure conditions, and maintenance.

As waterproofing experts, we highly recommend you do regular maintenance, make proper drainage, and protect from the UV lights in order to last long the waterproofing layer. Additionally, you can add a protective layer like gravel, tiles, or reflective coatings to prevent degradation from sun exposure, mechanical damage, and thermal expansion.

What Adhesives Can Be Used for Bituminous Waterproofing?

These 4 adhesives can be used to bond bituminous waterproofing sheets to different substrates.

- Cold-applied bituminous adhesives

- Hot bitumen (asphalt adhesive)

- Polyurethane-based adhesives

- Rubberized bitumen adhesives

Aqviz we highly recommend using the right primer before applying adhesives, which improves adhesion strength and prevents premature detachment. Additionally, solvent-based adhesives are preferred in damp environments since they cure faster and provide better water resistance.

How to Joint Bituminous Sheet Waterproofing?

Bituminous sheet waterproofing can be joined in the following 4 ways.

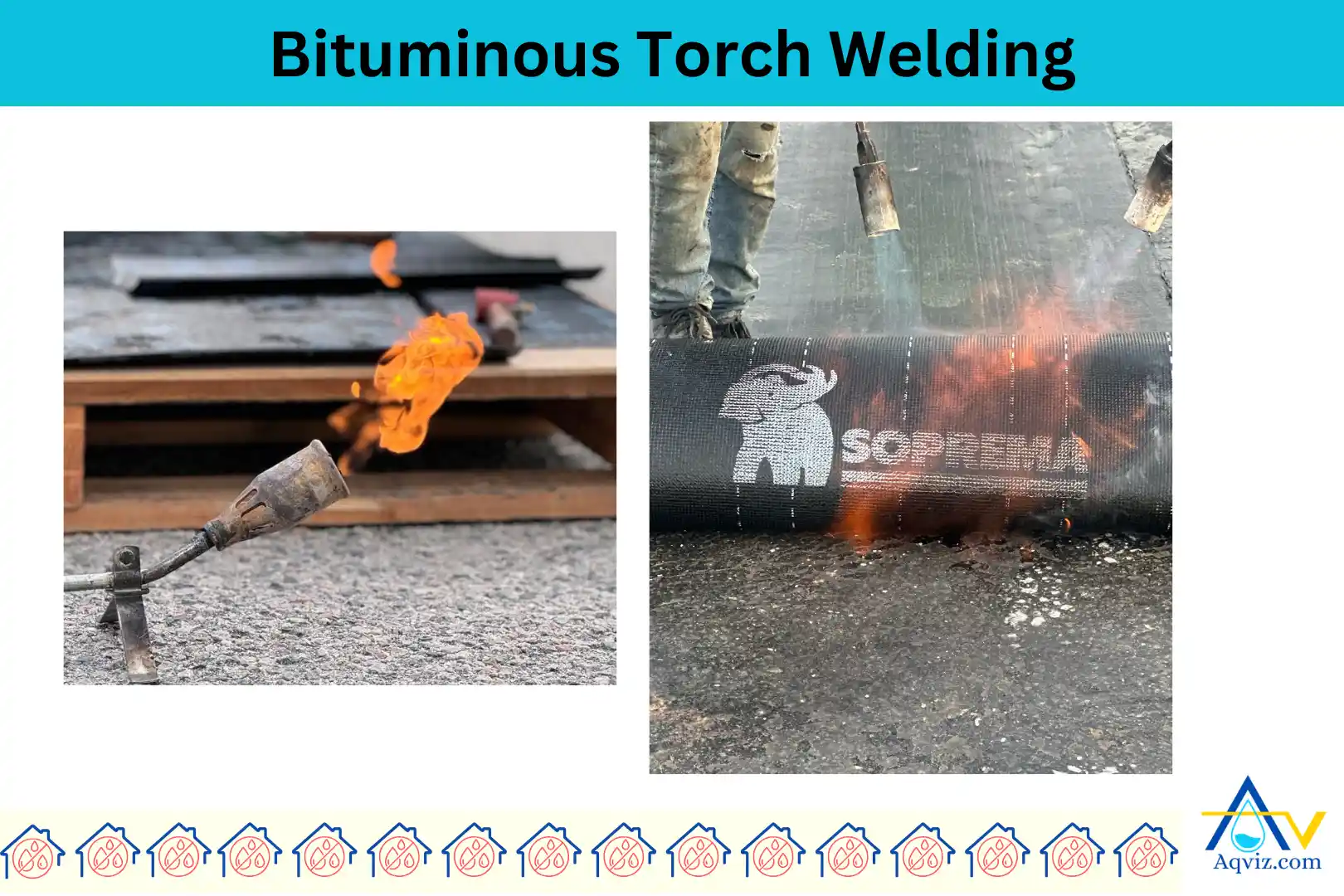

- Torch welding: Use a propane torch to heat the membrane. After melting sheet is joined with another by overlapping.

- Self-adhesive overlaps: Factory-applied adhesive strips are used to join the membranes without additional heat.

- Hot bitumen sealing: A layer of hot bitumen is applied between overlapping sheets when jointing.

- Cold adhesive bonding: A bitumen-based adhesive is applied between layers for jointing cold applied systems.

At Aqviz, we emphasize that seams should have a minimum overlap of 75mm to 100mm and be properly pressed to eliminate air pockets. After installation, a final inspection using a seam probe ensures there are no gaps or weak points that could lead to leaks.

What Are the Two Application Methods of Bituminous Sheet Waterproofing?

Bituminous sheet waterproofing membranes can be installed using two main methods as heat applied method and the cold applied method.

Heat applied method (Gas torch)

Heat applied method requires a propane torch to heat the lower surface of the bituminous sheet waterproofing membrane. The heat applied method is commonly used for SBS and APP modified membranes in roofs, basements, and podium decks. The heat applied method provides a strong, seamless, and durable bond, but requires a skilled application to avoid overheating and bubbling.

Cold applied method (Adhesive based)

In cold applied method uses bituminous adhesives, self-adhesive sheets, or hot bitumen to bond the membrane. Cold applied method is suitable for enclosed areas, wooden substrates, and projects where torching is a fire risk. Cold applied method is easier and safer to apply but requires longer curing time compared to heat-applied methods.

We recommend torch-applied membranes for large-scale roofing and exposed areas due to their high durability and seamless bonding. However, for sensitive applications like waterproofing insulation boards or interior spaces, cold-applied membranes are a safer and more practical option.

Read more: Ultimate Guide for Bituminous Coating Waterproofing

Where to Apply Bituminous Sheet Waterproofing?

Bituminous sheet waterproofing is widely used in various construction areas due to its flexibility, durability, and water resistance. It is particularly effective in the following applications:

- Roofing systems such as flat roofs, terraces, and balconies

- Basements & foundations in below-grade applications

- Podium decks & parking areas with high-traffic zones

- Tunnel & bridge waterproofing

- Wet areas (bathrooms & kitchens)

Read more about: Building Waterproofing: What You Should Know!

Environmental Factors Impacting Bituminous Sheet Waterproofing

Several environmental factors can affect the performance and longevity of bituminous sheet waterproofing:

- UV light: Prolonged sun exposure degrades standard bitumen membranes over time.

- Temperature extremes: Cold temperatures can make sheets brittle, while high heat may cause excessive softening.

- Moisture & humidity: High humidity slows down the curing process of adhesive-based applications and can trap moisture beneath membranes if not properly installed.

- Chemical exposure: Contact with oils, fuels, and aggressive chemicals may degrade bituminous membranes over time.

- Freeze-thaw cycles: In cold climates, water is trapped in the sheet membrane, and it can expand and cause cracks over time.

Pros and Cons of Bituminous Sheet Waterproofing

Pros of bituminous sheet waterproofing

- Bituminous sheet waterproofing is highly waterproof & flexible, adapting to structural movement.

- Bituminous sheet waterproofing has long lifespan (20–30 years) with proper maintenance.

- Bituminous sheet waterproofing has strong mechanical resistance against foot traffic and punctures.

- Bituminous sheet waterproofing has Good UV resistance with mineral-coated sheets.

- Bituminous sheet waterproofing can be applied over existing waterproofing, reducing cost.

Cons of bituminous sheet waterproofing

- Bituminous sheet waterproofing is not breathable, which can trap moisture if not properly vented.

- Bituminous sheet waterproofing is a heavy material, requiring skilled labor for proper installation.

- Bituminous sheet waterproofing is vulnerable to chemical damage from oils and strong solvents.

- Bituminous sheet waterproofing requires periodic maintenance to check for joint failures.

Bituminous vs. Cementitious Waterproofing: Key Differences

These are the key differences between bituminous vs cementitious waterproofing .

| Feature | Bituminous Waterproofing | Cementitious Waterproofing |

| Material Type | Bitumen-based membrane sheets | Cement-polymer modified coatings |

| Application | Torch-on, self-adhesive, or adhesive bonding | Brush, roller, or spray application |

| Flexibility | High: adapts to movement | Low: rigid and brittle over time |

| Durability | 20-30 years with maintenance | 10-15 years with proper application |

| UV Resistance | High (mineral-coated sheets) | Moderate (needs topcoat) |

| Chemical Resistance | Resistant to salts and mild acids | Excellent against strong chemicals |

| Breathability | Non-breathable – fully waterproof | Semi-breathable – allows some vapor diffusion |

| Best Use | Roofs, basements, podiums, bridges | Wet areas, retaining walls, swimming pools |

As waterproofing experts we can give you 2 solutions for the bitumen waterproofing. You can choose bitumen sheet waterproofing or you can choose bitumen coating waterproofing. After reading this guide we suggest you to choose the best one you need to apply on the surface. Else contact Aqviz expert for more information.