Submersible Sump Pump: Everything You Should Know

A submersible sump pump is a fully sealed, water-tight pump designed to operate while completely submerged in a sump pit with water. The main purpose of a submersible sump pump is to remove accumulated groundwater from a sump basin and discharge it safely away from a building’s foundation to prevent flooding, dampness, and structural water damage.

Submersible sump pump size is measured by the horsepower (HP), gallons per hour (GPH), and pumping head. Most available submersible sump pump sizes are ¼ HP, ⅓ HP, ½ HP, ¾ HP, and 1 HP. When selecting a submersible sump pump, you should consider the water table height, soil condition, rainfall data, and ground slope. If the groundwater accumulation is aggressive, you should use a 1HP submersible sump pump.

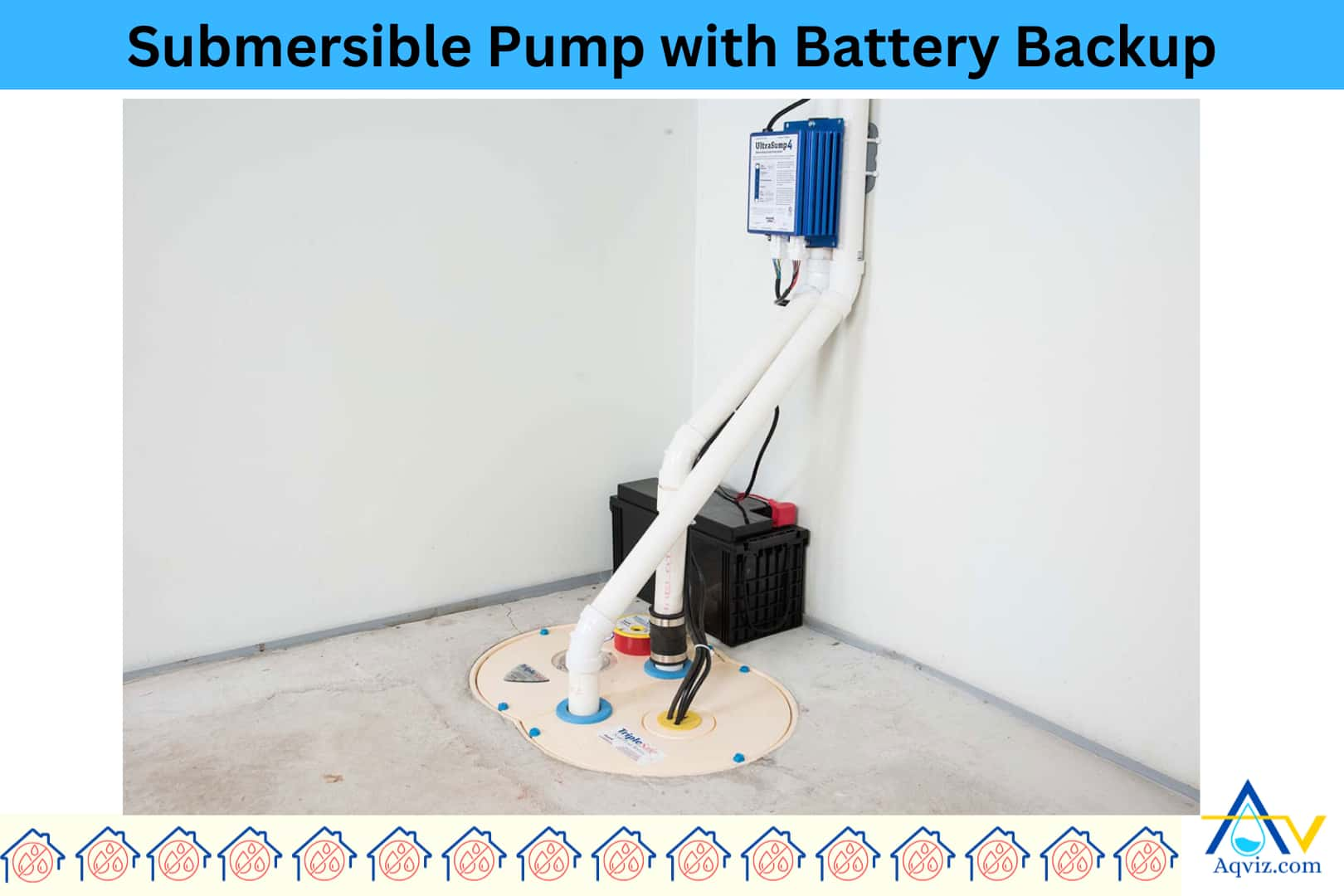

Sumberisble sump pumps are located in the sump basin by submerged in the water. Submersible sump pumps are powered by the AC voltage. The power for the submersible sump pump is provided by the domestic power line. When there is a power failure pump is powered by the battery backup. Submersible sump pumps are not noisy due to their submergence in the water.

As well as a submersible sump pump can typically last 7 to 10 years with proper installation, usage, and maintenance. But if there is poor maintenance, improper sizing, continuous power fluctuation, higher sedimentation, or corrosive water may cause damage to the submersible pump continuously.

To prevent this, Aqviz experts highly recommend you conduct relevant repairs and maintenance periodically. If there is a submersible sump pump problem, contact us soon. We will help you to fix it as soon as possible.

What Is a Submersible Sump Pump?

A submersible sump pump is a fully sealed, water-tight pump designed to operate while completely submerged in a sump pit with water. It is located at the bottom of the sump basin and automatically activates when rising water lifts the float switch and pumps water out through a connected discharge pipe. The motor and impeller are housed in a sealed casing to prevent water damage when it is submerged in water.

There are five key advantages of a submersible sump pump.

- Submersible sump pumps operate quietly since they’re submerged in water

- Submersible sump pumps are more powerful than pedestal pumps, ideal for high-volume drainage

- Submersible sump pumps save space with compact, in-pit installation

- Submersible sump pumps are better sealed against moisture and debris intrusion

- Submersible sump pumps are less likely to overheat due to constant water cooling around the motor

What Is the Main Purpose of a Submersible Sump Pump?

The main purpose of a submersible sump pump is to remove accumulated groundwater from a sump basin and discharge it safely away from a building’s foundation to prevent flooding, dampness, and structural water damage.

More than that, submersible sump pumps protect basements and crawlspaces from rising water tables, prevent mold, mildew, and indoor air quality issues, reduce hydrostatic pressure beneath foundation slabs, protect valuable items and appliances stored in lower levels, and keep finished basements dry and livable throughout the year.

Read More About: How Does a Sump Pump Work?

What Is the Size of a Submersible Sump Pump?

The size of a submersible sump pump is measured in horsepower (HP) and indicates how much water the pump can move per hour (GPH) and how high (Pump Head) it can lift it through the discharge line. Choosing the correct horsepower ensures the pump handles the expected volume of water without overworking or short cycling.

Standard submersible sump pump sizes range from ¼ HP to 1 HP. A ⅓ HP pump is suitable for most residential basements with moderate water entry, offering a flow rate of 2,400-3,000 GPH at 10 feet of lift.

For higher inflow, larger sump pits, or longer discharge distances, a ½ HP or ¾ HP submersible pump is more effective. In areas with frequent flooding or high groundwater, a 1 HP submersible sump pump unit may be required to handle aggressive water movement and prevent backups. Always match the sump pump size to the home’s drainage needs, not just the basin size.

To calculate the submersible sump pump size you can use this sump pump calculator tool which is improved by Aqviz experts.

What Is the Capacity of a Submersible Sump Pump?

The capacity of a submersible sump pump refers to how much water the pump can move within a specific time frame, usually measured in gallons per hour (GPH). This GPH rating determines how effectively the pump can keep up with incoming water during storms, groundwater rise, or plumbing leaks.

Typical submersible sump pump capacity ranges from 2,000 to 7,000 GPH, depending on the pump’s horsepower, discharge pipe size, and lift height (also known as head height).

For example, a ⅓ HP pump may deliver 2,400-3,000 GPH at a 10-foot lift, while a ½ HP unit can push up to 4,000-5,000 GPH. You should always select a submersible sump pump with a capacity that exceeds the expected peak water inflow to prevent water accumulation or basement flooding.

What Is the Voltage of a Submersible Sump Pump?

The voltage of a submersible sump pump refers to the electrical potential required to operate the pump motor. Voltage determines the compatibility with household wiring and ensures that the pump runs efficiently without overheating or losing power under load.

Most submersible sump pumps used in residential applications run on 120V AC (alternating current), which matches standard U.S. household outlets.

Larger or commercial-grade models may use 240V AC for higher pumping capacity. While most submersible pumps are AC-powered, some battery backup models operate on 12V or 24V DC through an inverter system. Always verify voltage requirements before installation to ensure safe and optimal operation.

How Much Power Need to Operate a Submersible Sump Pump?

The power needed to operate a submersible sump pump depends on the pump’s horsepower (HP), the required pumping height (head), and the system’s total load. The power of the submersible pump is measured in watts (W) and calculated based on the pump’s motor efficiency and electrical draw.

For example, a ⅓ HP submersible sump pump typically consumes 600 to 800 watts and can lift water up to 10-15 feet.

A ½ HP pump uses about 800 to 1,000 watts and handles head heights of 15-25 feet.

Larger ¾ HP to 1 HP pumps may require 1,200 to 1,800 watts, suitable for deep pits or long discharge runs. Always ensure your power supply matches the wattage requirement to avoid overloads or performance loss.

Is a Submersible Sump Pump Noisy?

No, submersible sump pumps are not very noisy. They are known for producing minimal operational noise because the motor is fully sealed and operates beneath the water inside the sump basin. The surrounding water acts as a natural sound insulator, significantly reducing vibration and mechanical noise during operation.

Compared to pedestal sump pumps, which have exposed motors above the pit and often generate a noticeable hum, a submersible sump pump runs quietly and smoothly. This makes it an excellent choice for finished basements, utility rooms, or any living space where noise control is important. Proper installation on a flat, vibration-resistant surface further reduces any residual sound.

How Long Can a Submersible Sump Pump Last?

A submersible sump pump can typically last 7 to 10 years with proper installation, usage, and maintenance. High-quality models with durable materials like cast iron housings and sealed motors may even last longer in ideal conditions.

Below factors contribute to reducing the durability of the submersible sump pump

- Frequent cycling due to undersized pumps or short float range

- Poor maintenance, such as clogged intakes or debris buildup

- High sediment or corrosive water, which wears down internal parts

- Improper sizing, causing the pump to run too hard or too long

- Power fluctuations or a lack of surge protection which damage the motor

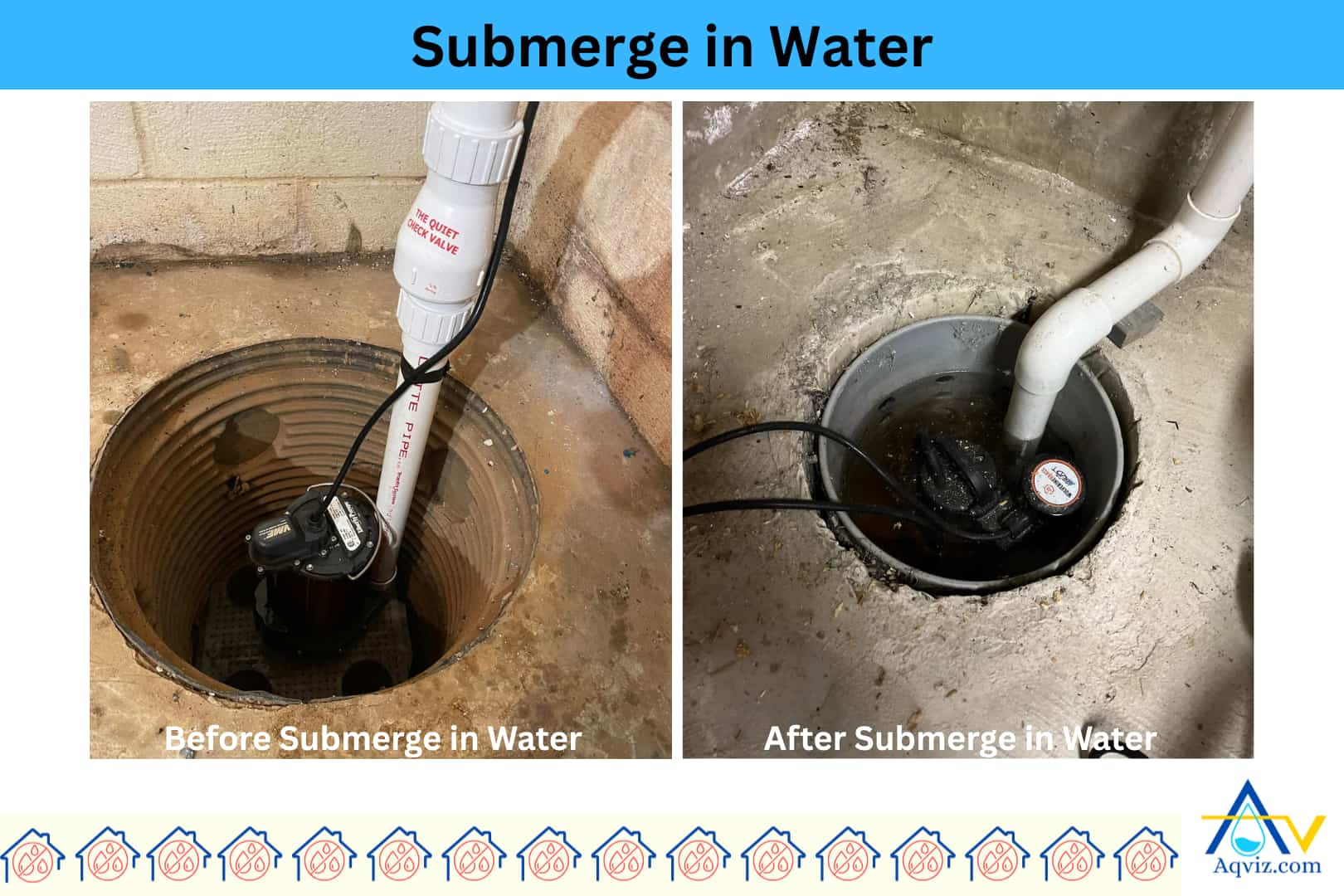

Where to Locate the Submersible Sump Pump?

A submersible sump pump should be located at the bottom of the sump pit, fully submerged in water when in operation. The sump pump should be installed at the lowest point of the basement or crawlspace, where water naturally collects due to gravity.

The submersible sump pump must sit securely on a flat, stable surface. It should be placed on a pump stand or a layer of clean gravel to prevent clogging from debris or sediment. The submersible sump pump should be submerged in at least 6 to 9 inches (15 to 23 cm) of water when it is activated, but it depends on the float switch design. Submerging the water submersible sump pump ensures proper cooling, reduces noise, and allows the pump to activate only when needed without dry running.

Read More About: How to Install a Sump Pump?

What Are the Disadvantages of Submersible Sump Pumps?

While submersible sump pumps are highly efficient and quiet, they do have certain drawbacks compared to other types like pedestal or water-powered sump pumps. Here are 7 disadvantages of using a submersible sump pump:

- Higher upfront cost than pedestal sump pumps

- More difficult to access for maintenance or repairs due to in-pit placement

- Risk of seal failure, which can allow water into the motor housing over time

- Shorter lifespan in dirty or debris-filled pits without proper filtration

- Heavier and bulkier than pedestal models, making installation harder

- Requires complete removal from the pit for inspection or replacement

- Not suitable for narrow sump pits, where a pedestal pump fits more easily

There are 5 types of sump pumps. Those types are better than submersible sump pumps in some cases. Read this 5 types of sump pump guide to know everything about them.

Is Submersible Sump Pump Better Than Pedestal Pumps?

Yes, a submersible sump pump is generally better than a pedestal pump for most residential applications, especially where power, quiet operation, and water-handling capacity are priorities.

Here are the main reasons why a submersible sump pump is considered superior:

- It runs more quietly since the motor is submerged and insulated by water.

- It handles larger water volumes and is better suited for heavy inflow or flooding.

- It’s fully sealed, protecting the motor from dust, moisture, and corrosion.

- It saves space, staying inside the pit and out of sight.

- It operates more efficiently under continuous or demanding conditions.