6 Types of Building Materials You Should Waterproof

Building materials waterproofing is the process or techniques used to make a material water-resistant or impermeable to water. Porosity and permeability are 2 of the main properties of the building material. These properties cause to water infiltrate through the building materials. Building materials should be waterproof In order to prevent water infiltration the materials. These are the 7 types of building materials with different porosities and permeabilities that need waterproofing

7 types of building materials need waterproofing

- Concrete

- Brick

- Tile

- Plywood

- Drywall panels

- Steel

Building materials can be damaged by the water If you do not waterproof. The most severe water damage of these materials are cracking, spalling, staining, decolorization, rotting, swelling, warping, mold and mildew growths, and rusting. In order to prevent these building materials should be waterproof using specific methods and membranes.

1. Concrete

Concrete is a composite building material made from cement, water, and aggregates. Concrete is a semi-solid mixture and when it hardens forms a strong, stone-like substance. Due to its hardness, it is widely used in building construction.

Concrete is a higher porosity and low permeability material in its natural state. As well as concrete consists of cracks, honeycombs, capillary pores, poor joints and sealing and construction defects which cause water from the material.

Prolonged water leaking can cause various types of damage, including cracking, spalling (surface flaking), efflorescence (white, powdery deposits), and rebar corrosion, which reduce the structural integrity of the concrete.

Hence concrete should be waterproof using internal waterproofing and external waterproofing methods. You can use admixture waterproofing as internal waterproofing while liquid and sheet membranes as external waterproofing. The most used liquid waterproofing membranes for concrete waterproofing are cementitious waterproofing, acrylic waterproofing, and polyurethane waterproofing. PVC, HDPE, EPDM, and Bituminous sheet membranes are the most used sheet waterproofing membranes.

2. Brick

Brick is a traditional building material made from clay and fired between 800°C to 1200°C. Bricks are used for the construction of walls, pavements, flooring and other structural elements.

Bricks have higher porosity and low permeability. Hence bricks seep water at a higher rate when it is fully saturated. Brick seepage is higher than the concrete seepage. This characteristic leads to water-related issues when it is not properly sealed.

According to ASTM standards brick should not absorb 20% of water from its weight. If brick absorbs water more than this it can be damaged by the water. The common brick damage due to water is brick spalling, mold and mildew growth, brick collapse and deterioration.

To prevent these water damages bricks should be sealed using sealant on the brick surface. New brick walls are easy to seal while old brick walls are difficult to seal due to their surface damage.

3. Tile

Tile is a durable building material typically made from white clay, talc, sand, feldspar, dolomite and calcite. Tiles are mainly 2 types: Porcelain and ceramic. Tile is a solid and brittle material. Hence tile is used as flooring in various building elements.

Tile is a low porosity and low permeability material with compared to other building materials. It absorbs 0.5% of water. The tile is connected with grout lines.

Grout lines are low permeable and have low porosity. Hence water and vapour can transfer through the grout lines. Hence structure can be damaged due to water seepage. It causes staining marks on the surface such as mold and mildew growth, a musty smell and other types of water damage to the ceiling, walls and floors.

In order to protect these water damages tile substrates should be waterproofed using a suitable waterproofing method. Substrates can be built using concrete, brick, wood and metal. According to the substrate material waterproofing membrane should be used.

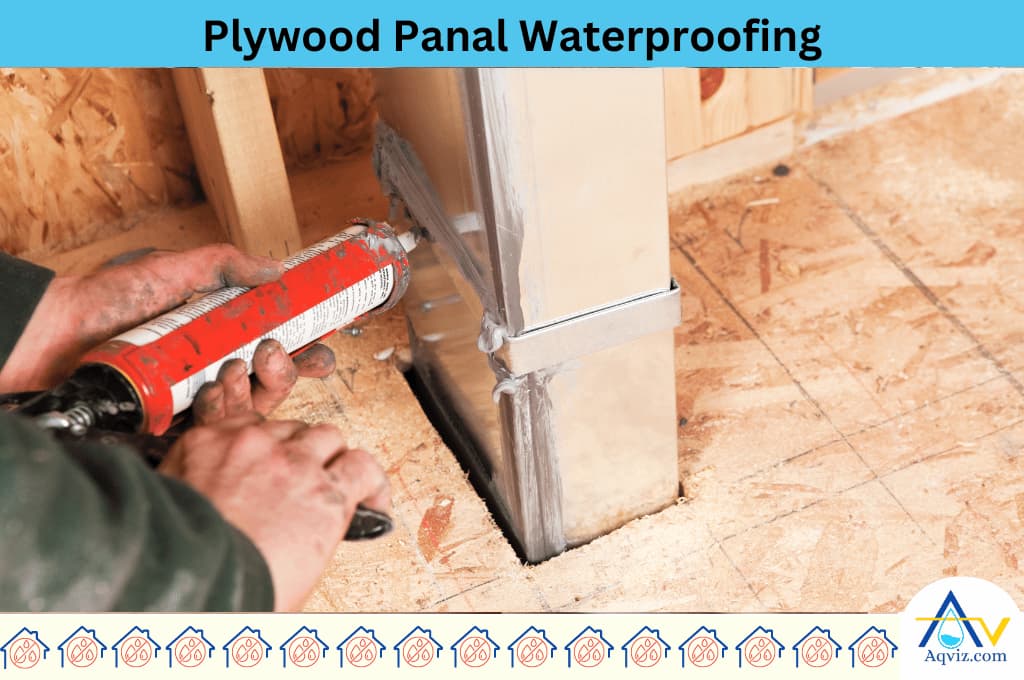

4. Plywood

Plywood is an engineered wood product made from layers of thin veneer sheets glued together with the grain of adjacent layers oriented perpendicular to each other. The main plywood types are BC, OSB, Hardwood, MDF, and RTD.

Plywood is made of wood and glue. When the plywood is exposed to water and moisture it causes warping, delamination, swelling, rotting, mold and mildew growth on the surface. These water damages reduce the structural strength of the aesthetic appeal.

In order to prevent these water damages plywood should waterproof using a sealant (sealant, latex paint, or oil-based stain) or waterproofing membrane.

You can also use weatherproof plywood such as marine grade plywood, pressure-treated plywood, medium-density overlay plywood, and high-density overlay plywood. These plywoods are highly water and moisture-resistant and are recommended for outdoor usage.

5. Wood

Wood is a natural construction material derived from trees. Wood is widely used in construction for framing, flooring, siding, and other applications due to its strength, versatility, and aesthetic appeal.

The porosity of the wood is between 40% – 80% with moderate permeability. Due to the porosity of the wood, it allows to absorb moisture through its cellular structure. This causes to serious water damage such as wood rotting, warping, swelling, splitting and cracking, and mold and mildew growth on the surface.

To protect the wood from water, the surface should be sealed using an oil-based sealer, water repellents, and varnishes.

6. Drywall Panels

Drywall panels, known as gypsum board or sheetrock, are construction materials used to create interior walls and ceilings in the building. Drywall panels consist of a layer of gypsum plaster sandwiched between two sheets of paper.

Drywall panels have low porosity and low permeability due to gypsum. However, the surface paper and the gypsum core can absorb moisture if exposed to water. When the drywall panels get wet and exposed to moisture over time it can warp, buckle, deteriorate, stain and mold and mildew growth on the drywall surface.

In order to protect drywall panels from water, it should be covered using a mold-resistant primer, and sealers. If the drywall is in higher water and moisture areas like bathrooms, and kitchens, it should be covered using a proper waterproofing membrane.

7. Steel

Steel is a versatile and strong material made primarily from iron and a small percentage of carbon. Steel is commonly used in construction purposes due to its higher compression and tensile strength.

Steel is a solid and impermeable material. It does not allow to pass water and vapour through the material. However, steel can be damaged due to chemical reactions with the water. Steel can corrode when it is exposed to water. The rate of corrosion can be increased by acidic water like rainwater. Due to water steel can corrode, rust formation, structural weakening and surface pitting over time.

In order to prevent these water damages steel surfaces should be sealed using a sealant like epoxy coating. Higher and more durable steel water protections are applying protective coatings like galvanization (zinc coating), powder coating, or specialized anti-corrosion paints that provide a robust shield against environmental elements.