How to apply Polyurethane Waterproofing?

When applying polyurethane waterproofing you should follow the proper steps and method statements to have last long polyurethane waterproofing membrane. As waterproofing experts, we are professionals for this.

We have prepared this step by step guide including all the tools, materials, and essential steps. So we highly recommend you follow these 7 step guide for polyurethane waterproofing for concrete, wood, and steel.

7 Steps for Polyurethane Waterproofing

- Provide the necessary tools and materials

- Clean the surface properly

- Prepare the surface for polyurethane waterproofing

- Apply primer on the surface

- Apply the polyurethane waterproofing membrane

- Curing the waterproofing layer

- Protect the waterproofing membrane

Step 01: Provide the Necessary Tools and Materials

Before applying polyurethane waterproofing, we must gather all the essential tools and materials to ensure a smooth and efficient application process. Aqviz highly recommends you use the right tools and materials always for the last long polyurethane waterproofing layer.

Tools for Polyurethane Waterproofing

- Wire brush or grinder (for surface preparation)

- Scraper or putty knife (for removing old coatings or debris)

- Paint roller (for large, even coverage)

- Paintbrush (for edges and corners)

- Trowel (for applying primer or thick coatings)

- Measuring tape (for accurate area calculation)

- Utility knife (for cutting reinforcement fabric or materials)

- Mixing drill with paddle (for uniform polyurethane mixture)

- Bucket or mixing container (for preparing the waterproofing compound)

- Safety gear (gloves, goggles, respirator mask, knee pads)

Materials for Polyurethane Waterproofing

- Polyurethane waterproofing membrane (single-component or two-component)

- Polyurethane primer (to enhance adhesion)

- Reinforcement fabric (for cracks, joints, and high-movement areas)

- Sealant or caulk (for sealing small cracks and gaps)

- Cleaning solvent (to remove grease and dust from the surface)

- Sandpaper or grinding disc (for roughening smooth surfaces)

- Masking tape and plastic sheets (to protect surrounding areas)

Now that we have our tools and materials ready, we can move on to preparing the surface before application.

Step 02: Clean the Surface Properly

Before applying polyurethane waterproofing , we must ensure the surface is completely clean, dry, and free from any contaminants that could affect adhesion. So you should follow the below steps 3 to clean the surface properly.

- Remove loose debris and dust: Use a broom, brush, or industrial vacuum to remove dust, dirt, and debris from the surface.

- Remove old coatings and loose paint: If the surface has old waterproofing, paint, or coatings, use a grinder, wire brush, or scraper to strip them off.

- Eliminate grease, oil, and stains: Apply a degreasing agent or mild detergent to areas with oil or grease stains. Then use a scrub brush or pressure washer (minimum 3000 PSI) to break down stubborn stains. After rinse thoroughly with clean water, allow the surface to dry completely.

If you do not clean the surface properly it may cause PU membrane blistering, peeling, and adhesion failure over time. So we strongly recommend you clean the surface properly.

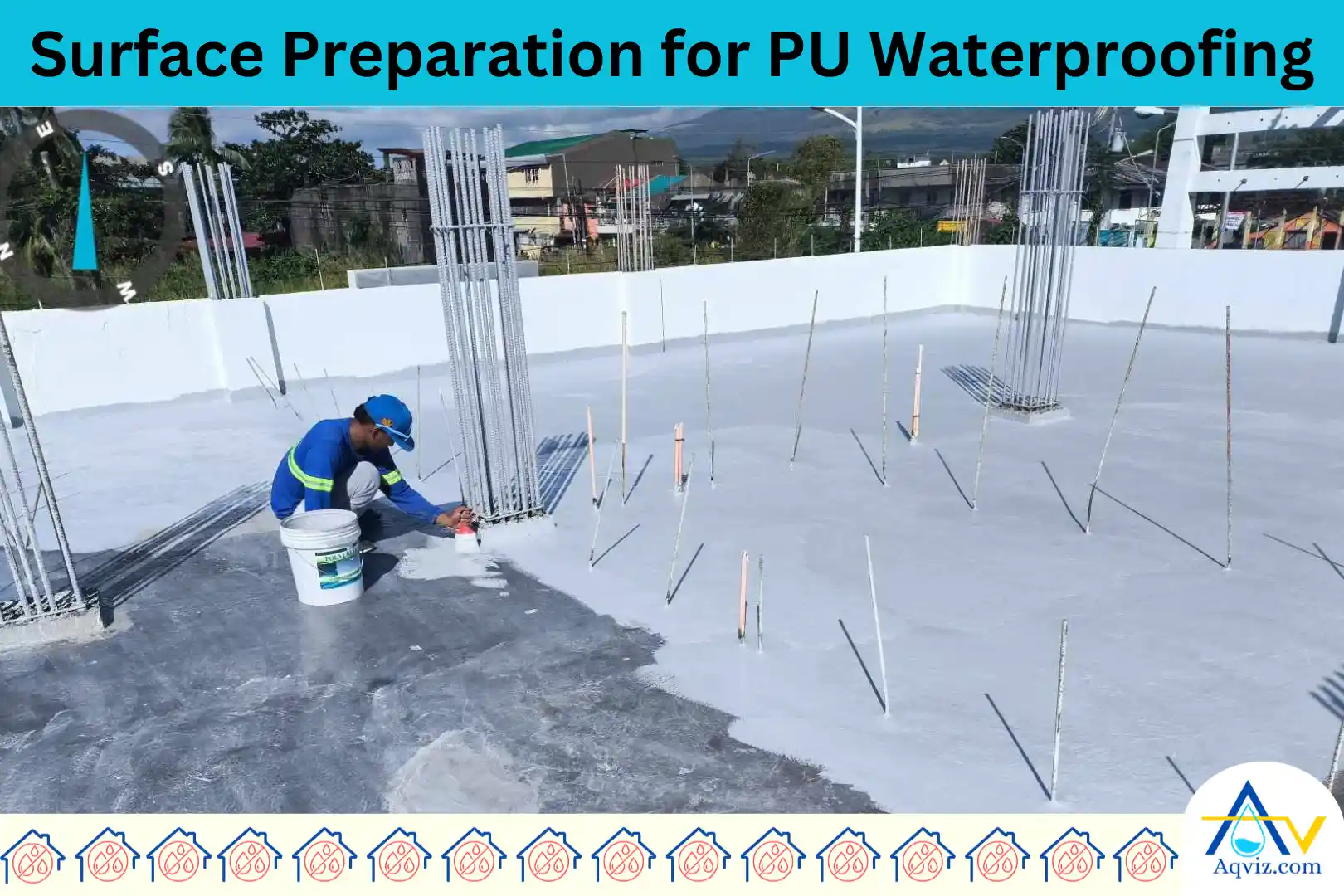

Step 03: Prepare the Surface for Polyurethane Waterproofing

After the cleaning process, you should prepare the surface for polyurethane waterproofing.

1. Inspect the surface for defects

- Carefully check for cracks, holes, weak spots, or structural damage. Pay special attention to corners, joints, and transitions, as these areas are prone to leakage.

2. Repair any surface imperfections

- For cracks and gaps: Use a polyurethane sealant or flexible joint filler to seal any visible cracks. For deep cracks, apply a backer rod before sealing.

- For uneven surfaces: If the surface has depressions or rough patches, apply a self-leveling mortar or cementitious repair compound to create a smooth finish.

- For joints and seams: Reinforce expansion joints, corners, and seams with fiberglass mesh or geotextile fabric to prevent movement-related failures.

3. Ensure a smooth and porous surface

- For concrete surfaces: If the concrete is too smooth, it must be roughened to improve adhesion. Use a diamond grinding machine, shot blasting machine, or sandpaper to create a slightly textured finish.

- For metal surfaces: Remove any rust using a wire brush, grinder, or rust converter, then clean with a degreaser.

- For wood surfaces: Ensure the wood is dry, sanded, and free from loose splinters.

Check for moisture content: Use a moisture meter to check the surface moisture level. It should be below 5% before applying the polyurethane membrane. If moisture is present, use dehumidifiers, or heaters, or allow natural drying for at least 48 hours.

Step 04: Apply Primer on the Surface

Applying a primer is an important step in polyurethane waterproofing because it enhances adhesion, seals porous surfaces, and ensures the longevity of the waterproofing system.

When you apply primer you should follow these 4 steps.

1. Choose the right primer for your surface

- Concrete & masonry surfaces: Use a polyurethane-based or epoxy primer for better penetration and adhesion.

- Metal surfaces: Apply a rust-inhibiting primer to prevent corrosion before waterproofing.

- Wood surfaces: Use a penetrating wood primer to ensure even absorption.

2. Prepare the primer mixture: If using a single-component primer, stir it thoroughly to ensure uniform consistency.

- If using a two-component primer, mix resin and hardener in the correct ratio (as specified by the manufacturer).

- Avoid over-mixing, as it may introduce air bubbles, affecting application quality.

3. Apply the primer evenly

- Use a roller for large areas and a brush for edges and hard-to-reach spots.

- Apply a thin and even coat to prevent pooling or excessive build-up.

- Work in one direction to ensure proper coverage.

4. Allow proper drying time

- Most primers take 4 to 8 hours to dry, but drying times can vary based on humidity and temperature.

- The surface should feel dry to the touch before applying the polyurethane waterproofing membrane.

- If the primer is left exposed for more than 24 hours, a second coat may be required to reactivate adhesion.

Step 05: Apply the Polyurethane Waterproofing Membrane

Applying the polyurethane waterproofing membrane is the most crucial step in achieving a seamless, durable, and watertight surface. This process requires precision, proper layering, and adherence to the manufacturer’s guidelines.

Before starting the application, it’s important to know which type of polyurethane membrane you are using:

Mixing the Polyurethane Waterproofing

Single-component PU (one-part) membranes are pre mixed and ready to use.

Two-component PU (two-part) membrane requires mixing resin (Part A) and hardener (Part B) in a specified ratio (usually 1:1 or 2:1). We highly recommend you to mix it with a mechanical drill mixer at low speed to avoid air bubbles.

- Use a mixing drill with a paddle attachment for at least 3-5 minutes to achieve a homogeneous, lump-free mixture.

- Avoid excessive mixing, as it may introduce air bubbles, leading to pinholes in the final coating.

You can choose one of these 6 Types of Polyurethane for your project for the best performance.

Applying the Polyurethane Waterproofing

Apply polyurethane waterproofing as follows on the surface

- Use a paint roller, brush, or airless spray to apply a thin and even PU coat.

- Start from one end and work in uniform strokes, ensuring full coverage over the space.

- The thickness of the first PU coat should typically be 0.8-1 mm.

- Pay extra attention to corners, wall-floor junctions, and penetrations (pipes, drains, edges) because these are prone to high leaks.

- Let the first layer to dry. The first coat must fully cure before applying the second layer.

- Then apply the second coat perpendicular to the first coat (cross-layer application). The second layer helps to improve coverage and eliminates weak spots.

- Ensure the second coat is slightly thicker (1.0-1.2 mm) than the first for better durability.

Step 06: Curing the Waterproofing Layer

After applying the waterproofing layer on the substrate you should wait for the curing. Curing is the process of allowing the polyurethane waterproofing membrane to dry and harden properly, ensuring it achieves its maximum strength, flexibility, and waterproofing performance. This step is essential to prevent premature failure, poor adhesion, and weak spots in the coating.

- Initial drying time of the PU waterproofing: 6 -12 hours (surface becomes touch-dry)

- Full cure of PU waterproofing before water exposure: 24 – 48 hours

- Complete curing of PU waterproofing for maximum strength: 3-7 days

Not only that, you should pay attention to the humidity and environmental temperature. Because higher humidity and lower temperatures slow down the curing process.

Aqviz highly recommends you have better ventilation on the surface. Because higher ventilation and warm temperatures speed up the curing process.

Step 07: Protect the Waterproofing Membrane

Now we are in the last step, This is important, for the last long polyurethane membrane.

After applying and curing the polyurethane waterproofing membrane, it’s crucial to protect it from mechanical damage, UV exposure, chemical spills, and wear and tear. Without proper protection, the membrane can deteriorate prematurely, compromising its waterproofing ability.

- Apply a protective topcoat (for UV and chemical resistance)

- Use protective layering for heavy traffic areas

- Avoid sharp objects and heavy impact

- Prevent chemical and oil spills

- Inspect and maintain regularly