HDPE Waterproofing: Know About Properties, Usage, Installing, and Protection

HDPE waterproofing is a water-impervious layer made by using High-Density Polythylene material. HDPE is a 1.5 mm thicker sheet-type waterproofing membrane. It can lay on the substrate by connecting the joints and seams. A self-adhesive HDPE waterproofing membrane is a type of HDPE waterproofing membrane that consists of a self-adhesive backing.

HDPE waterproofing membranes consist of important properties such as water resistance, UV resistance, chemical resistance, flexibility, durability, and high thermal stability. These properties improve the waterproofing capabilities of the HDPE layer.

You can use HDPE waterproofing on foundations, basements and slabs. Moreover, HDPE can be used as a sheet waterproofing membrane in buildings, plaza decks and balconies, underground parking garages, retaining walls, elevator pits, planter boxes, crawl spaces and swimming pools.

You can use these 5 most popular HDPE waterproofing products such as Henry Blueskin WP200, CETCO CoreFlex, HDPE Bentonite Sheet Waterproofing Membrane, HydroBan Sheet Membrane by Laticrete, Ultra-Shield Pre-Pave and Pre-Deck by Polyguard. You can install the HDPE waterproofing membranes using these products by following the steps mentioned below. You should always follow the proper methods and manufacturer guidelines to join and seal the waterproofing layer.

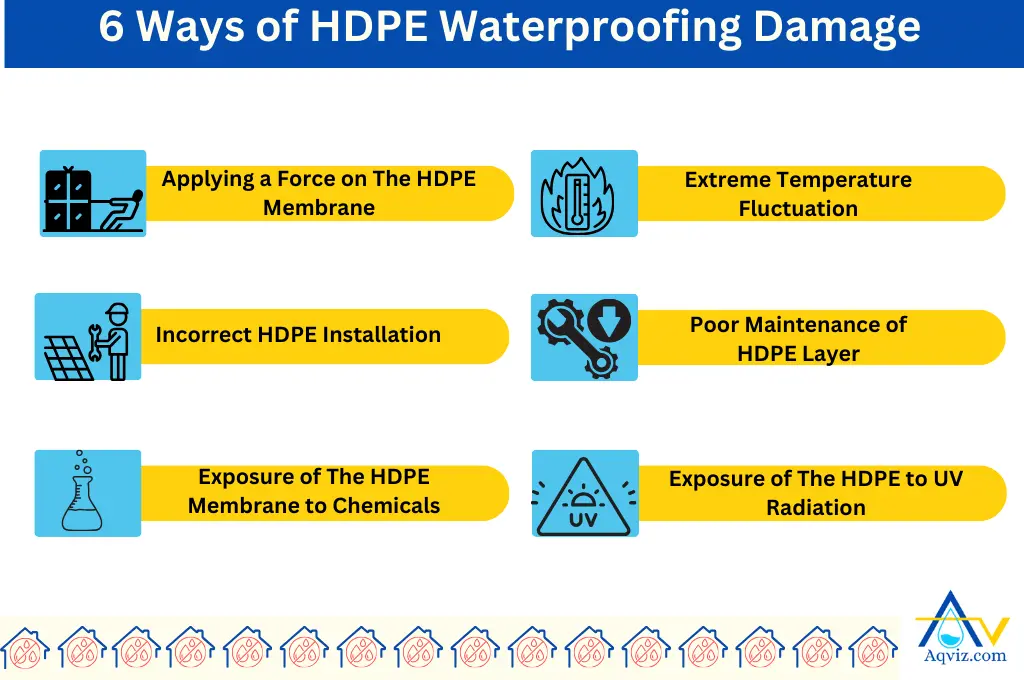

Installed HDPE layers can be damaged due to physical impact, incorrect installation, exposure to harsh chemicals, exposure to UV radiation over time, higher temperature fluctuation, and poor maintenance. These damages cause water to leak through the membrane.

But you can protect the HDPE membranes by doing the proper installation, regular inspection, avoiding excess stress on the layer, applying UV-protected sealants or coating on the surface, doing regular cleaning on the HDPE membrane, and making the proper drainage system around the HDPE layer.

Bentotie HDPE waterproofing is a combination waterproofing membrane consisting of bentonite and HDPE. You can use a PVC waterproofing membrane instead of HDPE. But HDPE is always better than the PVC membranes.

What is HDPE Waterproofing?

HDPE waterproofing is a water-impervious layer made using High-Density Polyethylene material. HDPE is a sheet-type waterproofing membrane that has important waterproofing properties, such as being water-resistant, UV-resistant, chemical-resistant, flexible, durable, and highly thermal stable. Therefore, HDPE can be used to prevent water leaking on foundations, basements and roofs.

What is self-adhesive HDPE Waterproofing?

A self-adhesive HDPE waterproofing membrane is a type of HDPE waterproofing membrane that consists of a self-adhesive backing. Self-adhesive HDPE membranes are designed for ease of installation on the substrate to reduce the additional adhesives or bonding agents during the waterproofing installation process.

What to Know About HDPE Waterproofing Properties?

The most important HDPE waterproofing properties are water resistant, UV resistant, chemical resistant, flexibility, durability, and thermal stability. HDPE waterproofing properties can be varied with the manufacturer but all of the properties should be in the ASTM standards.

What is the Thickness of HDPE Waterproofing?

The average thickness of HDPE (High-Density Polyethylene) waterproofing membrane is 1.5mm. But it can vary between 0.5mm to 2.5mm according to the usage requirements.

Is HDPE Waterproofing UV Resistant?

Yes, HDPE (High-Density Polyethylene) waterproofing is known to be UV resistant. HDPE membrane contains carbon black, which is an excellent UV stabilizer, and it resists the harmful effects of UV radiation. When this is exposed to heavy sunlight over time, it can deteriorate the material. Therefore, HDPE waterproofing is often covered or buried after installation to minimize UV exposure and prolong its lifespan.

Is HDPE Waterproofing Water Resistant?

Yes, HDPE (High-density polyethylene) is a waterproof and highly water-resistant membrane. Because HDPE is a non-porous material, it does not allow water to pass through easily. Therefore, it is often used in constructions that require high levels of water resistance.

Is HDPE Waterproofing Breathable?

No, HDPE (High-Density Polyethylene) waterproofing membranes are not breathable. HDPE installation creates a solid barrier that doesn’t allow water or moisture to pass through the membrane. Therefore it is used for roofs and basements to prevent water damage.

Is HDPE Waterproofing Chemical Resistant?

Yes, HDPE (High-Density Polyethylene) waterproofing is a chemical-resistant, water-impervious layer. Hence, it can be used for areas containing corrosive substances. But HDPE should not open to chemicals for a long time. That will cause brittles and cracks on the HDPE waterproofing membrane.

Is HDPE Waterproofing Thermal Resistant?

No, HDPE waterproofing is not a thermal-resistant waterproofing membrane. HDPE waterproofing can withstand a wide range of temperature fluctuations. Hence it can withstand extremely cold days in winter and hotter days in summer.

What is the Strength of HDPE Waterproofing?

HDPE has a tensile strength of 0.20 – 0.40 N/mm^2 and a puncture resistance of 150N for a 2mm thick sheet. However it can be varied with the thickness of the material and the manufacturer of the specific product.

What Building Components Can I Waterproof Using HDPE?

Using HDPE waterproofing membranes, you can waterproof mainly foundations, basements, and slabs. Moreover, HDPE can be used as a sheet waterproofing membrane in buildings, plaza decks and balconies, underground parking garages, retaining walls, elevator pits, planter boxes, crawl spaces and swimming pools.

HDPE Foundation Waterproofing

HDPE foundation waterproofing is a process of installing an HDPE waterproofing membrane on the foundation to prevent water damage due to leaking and seeping. HDPE can be used as a successful foundation waterproofing membrane because HDPE waterproofing membrane is a water-resistant, chemical-resistant membrane; hence foundation is not affected by water damage and chemical damage.

Due to the flexibility and durability of the HDPE waterproofing membrane, it can be installed on the foundation and does not need regular repairs and maintenance. HDPE waterproofing materials are high tensile strength and puncture resistant hence they can withstand excessive loads on the foundation.

HDPE Basement Waterproofing

HDPE can be used for basement waterproofing . HDPE waterproofing membranes can be installed both inside and outside the basements. HDPE is a thicker membrane; hence it can withstand high water pressure. Due to the chemical and UV resistance, the HDPE layer will protect from sunlight as well as chemicals. Due to the non-breathability of the HDPE membrane, it will not pass harmful gases inside the basement. Therefore, HDPE is a successful waterproofing membrane for basements.

HDPE Slab Waterproofing

HDPE slab waterproofing is laying HDPE membrane on the concrete slab in order to prevent the water from leaking into the structure. Due to the UY resistance of the HDPE, it can be used for outside slab waterproofing that is highly open to sunlight.

What are the Best HDPE Waterproofing Products?

The 5 best HDPE waterproofing products are Henry Blueskin WP200, CETCO CoreFlex, HDPE Bentonite Sheet Waterproofing Membrane by Volclay Voltex, HydroBan Sheet Membrane by Laticrete, Ultra-Shield Pre-Pave and Pre-Deck by Polyguard.

- Henry Blueskin WP200: This is a self-adhesive waterproofing membrane composed of an SBS-modified bitumen compound on the top and a silicone release film on the bottom. It is an ideal product for foundation walls, planters, retaining walls, and other below-grade applications.

- CETCO CoreFlex: This comprehensive waterproofing system combines the durability of HDPE with the flexible and flexible properties of a thermoplastic elastomer. Its dual-layer technology offers superior protection against water and gas ingress.

- HDPE Bentonite Sheet Waterproofing Membrane by Volclay Voltex: This waterproofing membrane incorporates HDPE with bentonite, a naturally swelling clay. When installed, the bentonite swells to form a tight, seamless barrier against water intrusion.

- HydroBan Sheet Membrane by Laticrete : This is a high-performance, low-perm waterproofing sheet membrane for use in interior, exterior, wet areas, and submerged applications. It provides unmatched waterproofing performance and detail handling.

- Ultra-Shield Pre-Pave and Pre-Deck by Polyguard: This is a tough, durable HDPE waterproofing membrane enhanced with rubberized asphalt adhesive for superior adhesion and longevity.

How to Install HDPE Waterproofing?

HDPE waterproofing can be installed by following the below steps. If you are a DIY enthusiast, it will take 2-3 days to finish the HDPE waterproofing membrane. For the skilled expert, it will take 1-2 days.

- Prepare the Substrate for HDPE installation – You should prepare the surface as clean, dry and free of any debris or sharp objects that could potentially damage the HDPE membrane.

- Measure the HDPE covering area – You should measure the area that you want to waterproof to estimate how much HDPE membrane you will need.

- Cut the Measured Length from the HDPE sheet – Cut the HDPE waterproofing membrane according to the measurements.

- Place the HDPE Membrane – Start to lay the HDPE membrane. You can begin from a corner and gradually unroll the membrane across the length of the area. Make sure there are no wrinkles or air pockets under the membrane.

- Connect the HDPE membrane seams and joints – You can use a suitable primer adhesive to connect the HDPE membrane’s seams and joints. You can use a heat gun to connect the membranes also. The connecting method of the HDPE membrane depends on the manufacturer’s guidelines.

- Inspect after HDPE is installed – Once installation is complete, inspect the entire surface to ensure all seams are well bonded and there are no gaps or blisters that cause to water leak.

- Protect the HDPE layer – Protect the HDPE membrane from any possible water leaking due to any mechanical damage. As a protection layer, you can use a form of cementitious screed, insulation boards or geotextile membrane below the HDPE layer.

How to Damage HDPE Waterproofing?

An HDPE waterproofing layer can be damaged due to physical impact, incorrect installation, exposure to harsh chemicals, exposure to UV radiation over time, higher temperature fluctuation and poor maintenance. A damaged HDPE waterproofing membrane always leaks the water. As a result of this, HDPE damage causes structural strength and aesthetic damage,

- Applying a force on the HDPE membrane: The HDPE membrane can be damaged due to the application of physical force on the HDPE waterproofing membrane.

- Incorrect HDPE installation: HDPE membranes can be damaged due to incorrect installation. Incorrect HDPE installation can cause loss of the seams and joints, wear and tear the membrane, and blistering on the membrane. Due to incorrect HDPE installation, water can seep through the layer.

- Exposure of the HDPE membrane to chemicals: HDPE waterproofing membranes are chemical resistant. But when it is open to chemicals for a long time, it can crack and become brittle. This can damage the membrane and leak the water through the membrane.

- Exposure of the HDPE to UV radiation: UV radiation can degrade the HDPE membranes when it open to sunlight over time. Due to degradation, the HDPE layer will fail under heavy water.

- Extreme temperature fluctuation: HDPE waterproofing membrane can be damaged due to extreme temperature fluctuations due to fatigue of the material. This causes the water to leak into the structure.

- Poor maintenance of HDPE layer: HDPE damages can be increased with poor maintenance and inspections.,

How to Protect HDPE Waterproofing?

Youcan protect the HDPE waterproofing membrane by following the below steps.

- Do regular inspecions and meinatennce

- Avoid excess stress on the DHPE membrane

- Do proper hDPE installation

- Protect the HDPE membrane against UV rays.

- Do regular cleaning on the HDPE membrane

- Use drainage boards.

What is Bentonite HDPE Waterproofing?

Bentotie HDPE waterproofing is a combination waterproofing membrane consisting of bentonite and HDPE. When combining HDPE and bentonite, it creates a composite membrane that provides two lines of protection against water.

If water passes through the HDPE layer, it will be absorbed by the Bentonite layer, which will swell to fill any gaps and prevent further water penetration. This makes Bentonite HDPE waterproofing highly effective for a variety of applications, including foundation seepage prevention, tunnel and subway construction, and more.

Is HDPE better than PVC Waterproofing?

Yes, HDPE waterproofing membranes are better than PVC waterproofing because HDPE waterproofing is more flexible, highly water resistant, chemical resistant, and UV resistant than PVC waterproof membranes. Also, the HDPE installation process is easier than the PVC installation process. When considering, the cost PVC is more expensive than HDPE. Therefore, HDPE is always better than PVC.

What is a PVC Waterproofing Membrane?

PVC waterproofing is applying the Polyvinic Chloride layer on the building substrate in order to prevent water penetration to the structure. PVC waterproof membranes are UV resistant, water resistant, have a wide range of thermal fluctuation, flexible, and durable. Hence PVC waterproofing membranes can be used for roofs, basements, slabs, and bathroom waterproofing. PVC is a sheet membrane waterproofing; therefore, you have to use a heat gun to weld the seams.

Can Bitumiuns Waterproofing be Used for Outdoors Like HDPE?

No, Bituminous waterproofing can not be used for outdoor purposes as HDPE waterproofing. Because the thickness of the bituminuns waterproofing can be changed with higher temperatures and rough surfaces. Hence bituminous waterprofing membranes are not recommended for outdoor usages with rough, and inclined surfaces. But HDPE can be used for a wide range of outdoor purposes.

Additionally, you should choose a suitable waterproof membrane for outdoor usage. When you select a waterproofing membrane , you should consider the environmental condition, surface condition, durability, compatibility, cost, maintenance and repair, warranty and support, flexibility, manufacturing standards, test results and performance data.