Building Waterproofing: What You Should Know

Building waterproofing is the process of installing a water-impervious layer on the structure substrate to prevent water penetration inside the material. Water-impervious layers are named as waterproofing membranes and those are two types: liquid and sheet waterproofing membranes.

Liquid waterproofing membranes are cementitious, epoxy, bituminous, acrylic and polyurethane. Sheet waterproofing membranes are PVC, HDPE, EPDM, bituminous sheet and Hypolan. These waterproofing membranes are installed in the building in two techniques: positive side and negative side waterproofing

Waterproofing membranes are installed in the building envelopes such as basements, bathrooms, swimming pools, garages, roofs, and concrete floors in order to prevent water damage. You should install the waterproofing membrane on the structure during its construction or when you see water damage in the envelope.

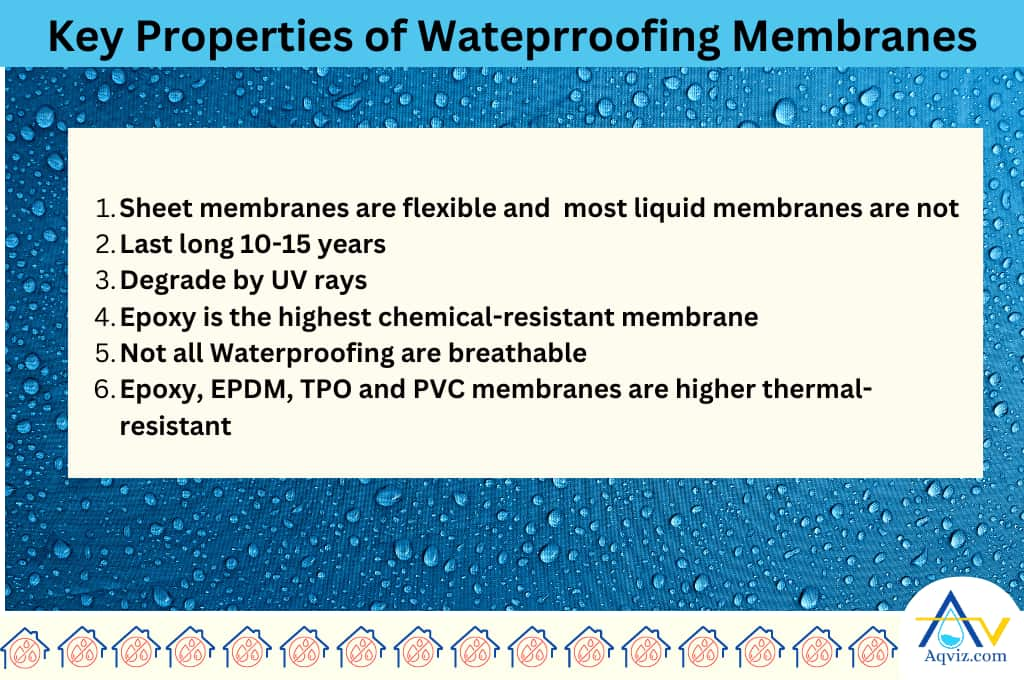

Waterproofing layers consist of different properties based on the type of membrane used. Not all waterproofing membranes are flexible and breathable. Waterproofing membranes can degrade when exposed to direct sunlight. The lifespan of the waterproofing layer typically ranges from 10 to 15 years.

To enhance adhesion between the substrate and the waterproofing membrane, a primer is often applied. Epoxy is the most chemical-resistant waterproofing membrane and EPDM, TPO, and PVC are the most thermally stable membranes. The cost of installing a waterproofing membrane varies depending on the materials and tools required. Proper maintenance and the use of specialized tools are crucial for ensuring optimal efficiency and durability.

Environmental impacts, sunlight, chemicals, high water pressure and human activities, cause damage to the waterproofing membranes. In order to prevent damage in waterproofing membranes you should use a proper waterproofing brand and experienced waterproofing contractors always.

What is the Definition of Waterproofing?

In building waterproofing, the definition of waterproofing is the process of installing a water-impervious layer on the structure substrate to prevent water penetration inside the material. waterproofing layer layers are mainly 2 types: sheet waterproofing and liquid waterproofing membranes.

Basements, bathrooms, roofs, swimming pools, and water tanks, are the most waterproof building envelopes. Installing waterproofing on this building envelope help to enhance the durability of the structure, prevent water damage, protect against mold and mildew, improve indoor air quality, increase property value, reduce maintenance costs, and contribute to energy efficiency.

What are the 2 Waterproofing Techniques?

Waterproofing techniques are mainly 2 types according to the side of the application on the substrate. Those are positive side waterproofing and negative side waterproofing.

Positive-side waterproofing: Positive-side waterproofing is applying waterproofing materials to the exterior, or wet side, of the structure. This technique prevents water from entering the building by creating a barrier on the side directly exposed to moisture, such as the outer surface of a foundation wall.

Negative-side waterproofing : Negative-side waterproofing is applying waterproofing materials on the interior side of the structure (dry side). This technique is used when water has already penetrated the building material, and the goal is to prevent it from moving further into the interior spaces. Negative side waterproofing is mostly used in basements, and tunnels.

Positive-side waterproofing is the most efficient waterproofing technique but it is not cost-effective for substrate preparation.

What is a substrate?

The substrate is the base material of the structure where the waterproofing layer is installed. Concrete, brick, wood, metal, stone, and tile are the most used substrates in building waterproofing. In order to increase the adhesiveness of the substrate primer is applied before installing the waterproofing layer.

What Building Envelope Needs Waterproofing?

These building envelope need waterproofing such as basement, bathroom, swimming pool, garage, roofs, concrete floors, metal floors, decks, water tanks, foundations, balconies, patios and elevator pits.

- Basement : You should waterproof the basement to prevent water infiltration from groundwater. Basement waterproofing helps to avoid structural damage, mold growth, and the deterioration of building materials.

- Bathroom : You should waterproof the bathroom floor and walls to prevent water damage due to constant exposure to moisture and humidity. Bathroom waterproofing stops potential leaks in the bathroom that cause mold growth, tile and grout deterioration

- Swimming Pool : You should waterproof the swimming pool area to prevent water leakage and damage to the surrounding structure. Swimming pool waterproofing helps to maintain the pool’s structural integrity, prevents soil erosion, and avoids water damage.

- Garage : Garage waterproofing is essential to prevent water infiltration from rain and snow, which can lead to rusting of metal components, deterioration of flooring, and damage to stored items in the garage.

- Roof : You should waterproof the roof to prevent water penetration from rain and snow. Roof waterproofing helps avoid leaks, which can cause interior damage, mold growth, and structural issues.

- Concrete Floor : Concrete floor waterproofing helps to prevent moisture from seeping through and causing damage to the underlying structure. It helps to prevent mold growth, structural damage, and staining marks on the surfaces.

- Metal Floors : Metal floor waterproofing helps to prevent water corrosion and rusting, which can compromise the floor’s structural integrity. It helps to maintain the floor’s strength, appearance, and longevity, reducing maintenance.

More than that other building envelopes such as decks , water tanks , foundations , balconies , patios and elevator pits should be waterproof in order to protect the structure from the excessive water.

These building envelopes should be waterproofed using a proper waterproofing membrane.

What are the Waterproofing Membranes?

Waterproofing membranes are types of impervious layer that prevent water from penetrating through the layer. Waterproofing membranes are manly 2 types: liquid waterproofing membranes and sheet waterproofing membranes.

Liquid waterproofing membranes can be applied on the substrate in a liquid form. When it dry It creates a non-seam layer over the substrate and stops the water from penetrating through. The most used liquid type waterproofing are cementitious waterproofing , epoxy waterproofing , bituminous waterproofing , acrylic waterproofing , polyurethane waterproofing and admixture type waterproofing .

Sheet waterproofing membranes are ready-made waterproofing layers which stop water from penetrating. Sheet membranes should be connect together by using heating methods or gluing to make sealed surface on the substrate. The most used sheet waterproofing membranes are PVC waterproofing membrane , HDPE waterproofing membrane , EPDM waterproofing membrane , Bituminous sheet waterproofing membrane , and Hypolan waterproofing membrane.

What are the Waterproof Materials?

Waterproof material is a substance or product designed to prevent water from penetrating or passing through the material. As an example, waterproofing caulk. Waterproofing caulk is highly resistant to water and it is used to seal gaps and space of connections. As well as epoxy grout , waterproof paint , and waterproof cement are the most used waterproof materials.

As well as waterproofing material can be created by installing waterproofing techniques on the material. As an example concrete waterproofing. Concrete material can be waterproofed using specific technologies and improve its water resistance to the next level. The most improved waterproofing methods are concrete waterproofing , brick sealing , and plywood waterproofing .

When Should a Building Envelope be Waterproofed?

A building envelope can be waterproofed in two scenarios. First, the structure can be waterproof during the construction process. Second, the structure can be waterproof when a structure tends to be damaged from the water.

When the structure is constructed, it can be waterproofed using required waterproofing membranes and materials. This is a highly cost-effective, optimised, more efficient, and long-lasting method.

When the constructed structure is getting damaged by the water, it should be waterproofed. You can see water-related issues in the structure. The most common water-related issues are water leaking, water standing, higher humidity levels, water standing, flooding, and water seepage. These water-related issues cause water damage to the structure. The severe water damages are mold and mildew growth, musty smell, wall staining marks, paint peeling, wall cracking, wood rotting, wood warping, wallpaper bubbling, and decolourization on the surface.

When these problems are observed in the structure, it should be waterproof using a suitable waterproofing membrane to prevent further water damage.

What are the Properties of a Waterproofing layer?

The most important properties of a waterproofing layer are water resistance, flexibility, durability, adhesion, breathability, chemical resistance, UV resistance, thermal resistance, strength, cost-effectiveness, and repairability. These properties of the waterproofing layer are varied with the waterproofing membranes.

Are all Waterproofing Membranes Flexible?

No, all waterproofing membranes are not flexible. Liquid waterproofing membranes are mostly rigid and sheet waterproofing membranes are mostly flexible. However, some liquid waterproofing membranes form a flexible surface when it is drying.

Flexible waterproofing membranes are highly recommended for vibrated surfaces, settling structures, and unstable structures. Hence sheet waterproofing is last long on these unstable structures.

How long can a Waterproofing Layer Last?

A waterproofing layer can last about 10-15 years if it is well-protected, repaired and maintained properly. The durability of the waterproofing layer can be improved by preventing exposure to UV lights, chemicals, vibrations and other physical damages.

What Happens When Waterproofing Layers Open to Direct Sunlight?

When a waterproofing layer is directly exposure to sunlight, it tends to degrade the waterproofing layer due to UV light in the sunlight. UV light can degrade the waterproofing membrane when it is directly exposed to sunlight. In order to prevent this waterproofing layer should be protected by UV light by applying a suitable sealant on the top of the membrane.

What is the Highest Chemical-Resistant Waterproofing Layer?

The highest chemical resistance waterproofing membrane is EPOXY. Epoxy waterproofing forms a rigid surface which is highly resistant to chemicals and oils. Hence epoxy is mostly used in garages, and chemical storage warehouses.

How can the Adhesion of a Waterproofing Layer be Improved?

The adhesiveness of a waterproofing layer can be improved by using clean, dust and debris-free substrate with applying a suitable primer on the substrate. Primer provides as sealed surface to the waterproofing layer and it increases the adhesiveness of the waterproofing layer with substrate.

Are all Waterproofing Layers Breathable?

Not all waterproofing layers are breathable. Breathability is transferring vapour water through the waterproofing layer except for liquid water. Vapor water can increase the humidity which causes many water-related damages. Hence most waterproofing membranes are not breathable.

Is the Waterproofing layer Thermal Resistant?

The thermal resistance of a waterproofing layer depends on the layer type of the material and its intended application. The most thermal-resistant waterproofing membranes are bituminous waterproofing, EPDM, TPO, and PVC. This material can handle the heat to a certain extent. But those are not fully thermal resistant.

What are the Costs of Building Waterproofing?

The cost of building waterproofing are mainly 2 types: material cost and labour cost. The material cost of a waterproofing project is based on the cost for the material, tools, instruments, power supply, and transportation. The labour costs of the waterproofing project are the cost for consulting and labour.

What are the Waterproofing Tools?

When you conduct a waterproofing project you will need these waterproofing tools such as waterproofing tape, epoxy injection gun, heat gun, seam roller, mixing paddle, pressure washer, bucket, paintbrushes, paint rollers, sponge, utility knife, scraper, measuring tape, spirit level, caulking gun, flashlight, spatula, grout float, safety gloves, safety goggles, and knee pads.

How to Maintain a Waterproof Building?

You can maintain a waterproof building by following 8 ways.

- Inspect the waterproofing layer regularly

- Repair any leaks and damages on the waterproofing membrane

- Check the waterproofing system and water-draining system

- Seal cracks and joints on the waterproofing membrane

- Reduce higher humidity levels

- Maintenance proper grading and angles

- Cover the waterproofing layer from sunlight

- Stop waterproofing layer exposure to chemicals

- Prevent cutting and drilling on the waterproofing layer

These 8 ways help to prevent damage to the waterproofing layer and increase the integrity of the building waterproofing.

What are the Environmental Impacts of Building Waterproofing?

The environmental impact affects the efficiency of the waterproofing layer. Environmental impacts such as direct sunlight, rain, snow, soil erosion, soil settlement, soil expansion, frost heave, tree roots, natural drainages and water table fail and damage the waterproofing membrane in the buildings.

Hence in order to prevent these environmental impacts, a waterproofing layer should be installed in the building envelope with a proper drainage system, protective coatings, soil stabilizing and installing suitable waterproofing membrane in the building envelope.

What are the Popular Waterproofing Brands?

These are the most popular and well-known waterproofing brands .

- BEHR

- Semco

- KILZ

- DRYLOK

- Liquid Rubber

- Sika

- Mapei

- Laticrete

- Tremco

- BASF

- W.R. Meadows

Who are the Trusted Waterproofing Contractors?

These are the most trusted and most reviewed waterproofing contractors .

- Everdry Waterproofing

- USA Waterproofing

- United Waterproofing

- Permaseal

- AquaGuard Foundation Solutions

- Basement Systems

- DryZone Basement Systems

How to Damage a Waterproofing Layer?

These are the 8 ways to damage a waterproofing layer .

- Physical impacts: The waterproofing layer can be damaged by heavy objects, sharp tools, or construction equipment that can puncture or tear waterproofing membranes, creating vulnerabilities where water can penetrate.

- Improper installation: Incorrect application techniques, such as inadequate surface preparation, improper overlap of seams, or incorrect curing times, can lead to weak points and potential failure of the waterproofing layer.

- Chemical exposure: The waterproofing layer can be damaged due to exposure to harsh chemicals, solvents, or cleaning agents can degrade the waterproofing material, causing it to lose its protective properties.

- Extreme temperature fluctuations: The waterproofing layer can be damaged due to excessive heat or cold which causes waterproofing materials to become brittle, crack, or lose adhesion of the waterproofing layer.

- UV radiation: The waterproofing layer can be damaged by prolonged exposure to ultraviolet (UV) rays that can cause to breakdown of certain waterproofing materials, leading to degradation and reduced effectiveness of the layer.

- Improper maintenance: The waterproofing layer can be damaged due to lack of regular maintenance, such as failing to repair minor damages or not cleaning debris from surfaces, can cause small issues to escalate and damage the waterproofing layer.

- Structural movement: Structural movements such as shifts or settling of the building structure can stress the waterproofing layer, leading to cracks or detachment from the substrate.

- Higher water pressure: Excessive water pressure, particularly from hydrostatic pressure in below-grade applications, can force water through the waterproofing layer if it is not designed to handle such forces.

What are the Differences Between Sealant and Waterproofing?

Sealants and waterproofing membranes are two different materials. Sealants are designed to fill gaps, cracks, and joints, preventing water, air, or dust from penetrating specific points where materials meet, such as around windows and doors. The waterproofing membrane is a continuous barrier along the structural substrate like bathrooms, foundations, roofs, and walls.

What are the Waterproofing Additives?

Waterproofing additives are substances mixed with construction materials, such as concrete, mortar, or plaster, to enhance their water resistance and prevent moisture penetration. The most used waterproofing additives are Hydrophobic agents, water-repellent agents, latex additives, plasticizers, pozzolans, crystalline waterproofing agents and cementitious waterproofing agents.